Manuel Upton

New Member

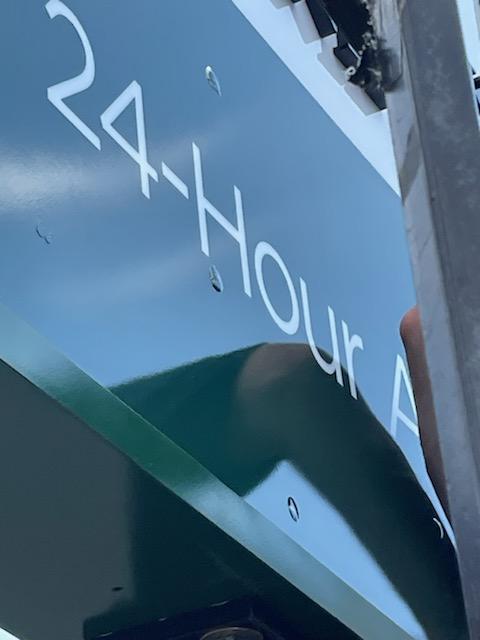

So, we are using a VG640 and ever since we changed to TR2 inks we are having bubbling issues when printing on 3M 40c-114R clear(only because my supplier was out of Arlon 4500 clear) laminated with Arlon3170 using the generic backlit Roland profile high quality setting, overprint set to 2 and sticking to polycarb. The bubbles only happen in the printed areas and not until the sign is exposed to heat. First time was back in March(Pizza photo), got a complaint a couple weeks after install. My supplier told me we may need to let the poly outgas longer. (I've never had to before), but on the next job we allowed the poly to outgas for a week after removing the liner. Installed that job in April ,sat in shop at least a week before faces were installed yesterday went to check it because of all the other issues and same thing. (Eastside Market photo) Looked great when faces were installed. Printed 4 more faces last week, let those outgas for the normal 2 days before laminating, poly outgassed for 3-4 days. Bank sign(24 Hour photo), installed vinyl on Thursday last week, sat on trailer inside shop til Monday. Looked fine before it left. Covered with a blanket 85-90 degree day 2 hour travel to site, uncover to giant green blisters. SMH We've been printing on clear with these settings for years with no issues til the inks changed. I'm about to do some tests using the same settings but sticking to different substrates. Any other thoughts or suggestions would be appreciated. Thanks!