PrinterMike

New Member

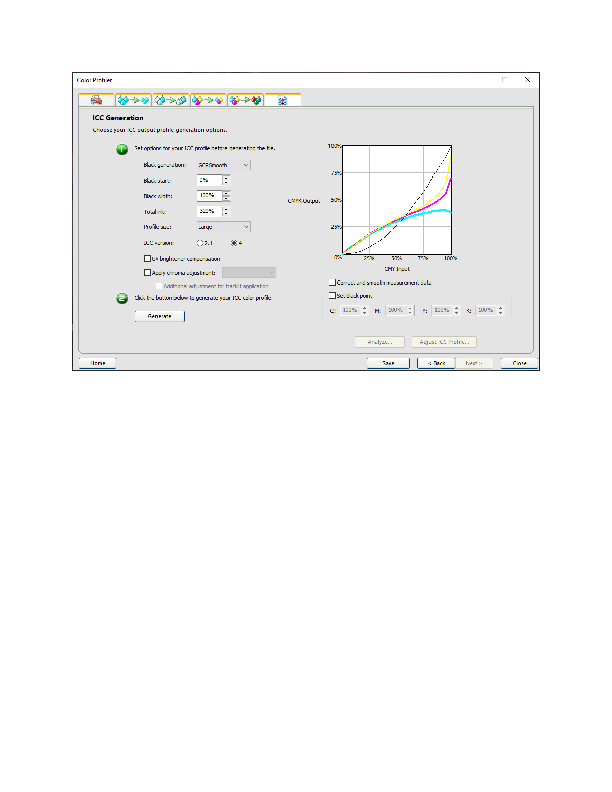

Our Epson 60600 has been banding so I tried making a new profile (which didn't fix the problem). I made the profile in Flexi Production Manager 21. In the final tab of the Color Pofiler it shows the cmyk curves. The myk curves look like typical curves, the cyan channel looks similiar up to 50% input and then tops out at about 40% output. I've tried profiling different media and putting heavy and light ink limits and it looks pretty much the same. What might be causing this (the cyan channel output to be so low)? I've attached a screen shot of the curve.

Thanks!

Thanks!