Here is the short story. I installed 2 brand new dx4 printheads on M&C-1&2 on my Roland SJ-1045ex. Worked about a month. The test-print on both of them is nearly perfect. BUT! the magenta one suddenly stopped firing (test print still perfect). After some powerful cleanings it worked again but after some time printing it stopped again.

• The test print is always perfect

• The dampers are full

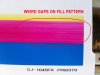

• On service mode FILL PATTERN at the beginning of the line there are some gaps "not regular banding"

• I have tried swapping the dampers with the other magenta head but nothing changed.

I have attached some pictures with the fill pattern, the test print and the moment it stops firing.

I have a massive experience on this machine (have changed over 10 printheads and many many other parts) but this is the first time i encounter something like this. If anyone had this problem and knows the solution, it would be great to share the info.

Thanks!

• The test print is always perfect

• The dampers are full

• On service mode FILL PATTERN at the beginning of the line there are some gaps "not regular banding"

• I have tried swapping the dampers with the other magenta head but nothing changed.

I have attached some pictures with the fill pattern, the test print and the moment it stops firing.

I have a massive experience on this machine (have changed over 10 printheads and many many other parts) but this is the first time i encounter something like this. If anyone had this problem and knows the solution, it would be great to share the info.

Thanks!