We are starting to print graphics for our many snack machines.

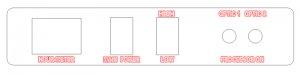

The snack machines we will be printing/laminating using 3M material and Graphtecing the curved "openings"(coin slot, front display, dispense opening, etc)

My question is, do I score the print on the plotter and then cut out on the table, or do I score, then apply the entire graphic, then cut out(carefully) after its applied to machine.

And I'm not talking about the edge cuts, only the openings.

This is only a front graphic(no sides) and its flat.

Any suggestions would be appreciated.

The snack machines we will be printing/laminating using 3M material and Graphtecing the curved "openings"(coin slot, front display, dispense opening, etc)

My question is, do I score the print on the plotter and then cut out on the table, or do I score, then apply the entire graphic, then cut out(carefully) after its applied to machine.

And I'm not talking about the edge cuts, only the openings.

This is only a front graphic(no sides) and its flat.

Any suggestions would be appreciated.