-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need Help CJV30-60 nozzle test blank

- Thread starter justroll

- Start date

Print Master 03

New Member

If no any error this mean that head work. If you see print head test before buying I mean hean cant dead. Check clean system of printer maybe print hard cant correct clean, and try manual push solvent to heat and check solvent easy going from head or have resistance if have resistance nedd clean head special liquid. Good luck!

Solventinkjet

DIY Printer Fixing Guide

Run a cleaning cycle and see if any ink moves into the waste tank. If it does and you still don't get any nozzles in the nozzle check, you probably have electrical issues. If no ink moves at all, you are probably just clogged up. I usually flush the pump out with cleaning solution to make sure it's not clogged and then change the cap top as well to make sure that's not the issue. If you have a clean pump and new capping station, you should at least be cable to get some nozzles firing.

thing is, i removed the cover from the head, and started a cleaning cycle , all the kinds the machine got , should i see this fluid moving to the dampers ? since the inkt in the dampers don't seem to move during this process at all...

since you are mentioning pump could be clogged this could be this issue then ? i hear the pump pumping .. i'll remove the right cover to so if i see something in the tubes ..

btw .. when i do pump tube wash and pump fluid into the cap (function key) it gets pumped away .. so i assume the pump is ok ?

since you are mentioning pump could be clogged this could be this issue then ? i hear the pump pumping .. i'll remove the right cover to so if i see something in the tubes ..

btw .. when i do pump tube wash and pump fluid into the cap (function key) it gets pumped away .. so i assume the pump is ok ?

Last edited:

Solventinkjet

DIY Printer Fixing Guide

When running a cleaning cycle you should see the dampers crush and a lot of the time you can actually hear it if it's quite in the room. Also, the pump can still make noise and be bad. The fact that solution flowed through it is a good sign that it's working. I would probably change the cap top next and see if that gets the ink flowing during cleaning cycles.

Thanks, i'll replace the capping station (i got a spare here) , also got new dampers just in case ...I was wondering if it's okay to flush the head with cleaing solution with minimal pressure ?

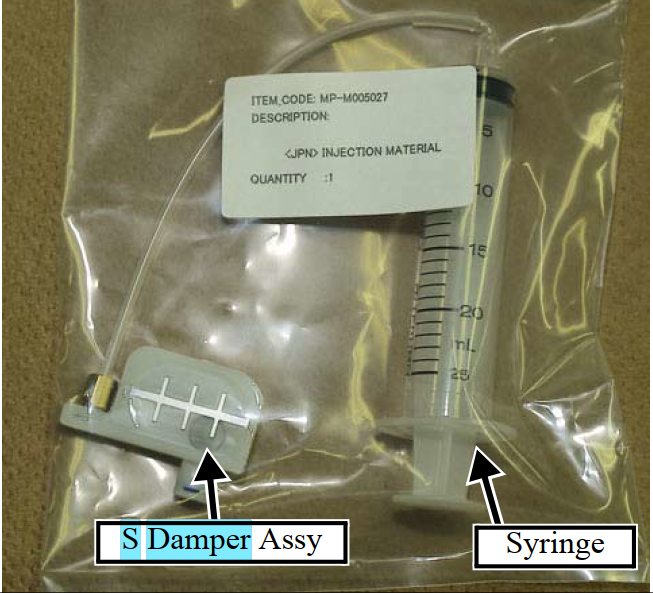

I see that for installing a new head mimaki advises to use a toolkit that as "S damper Assy", can't find the damper itself, is this required ? (i assume this is to avoid overpresurizing the input gates)

I see that for installing a new head mimaki advises to use a toolkit that as "S damper Assy", can't find the damper itself, is this required ? (i assume this is to avoid overpresurizing the input gates)

Solventinkjet

DIY Printer Fixing Guide

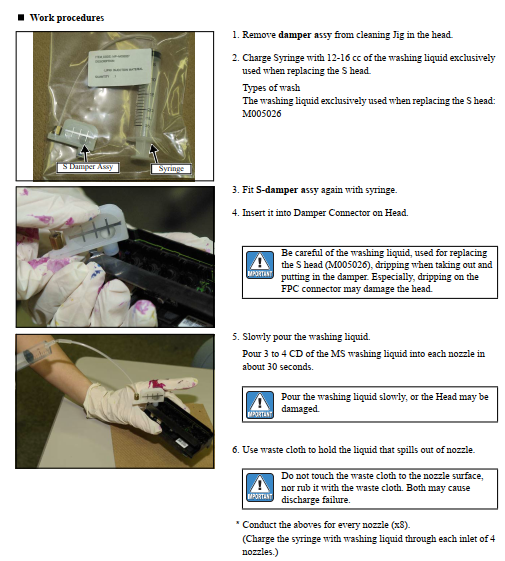

Thanks, i'll replace the capping station (i got a spare here) , also got new dampers just in case ...I was wondering if it's okay to flush the head with cleaing solution with minimal pressure ?

I see that for installing a new head mimaki advises to use a toolkit that as "S damper Assy", can't find the damper itself, is this required ? (i assume this is to avoid overpresurizing the input gates)

View attachment 147293

Yeah the official way is through the damper but honestly I always just hook the syringe directly up to the manifold. Push lightly until you see the solution bubbling out and then push a little harder and you should see solution spray out of each nozzle clearly. Just know that there is always a possibility that you damage the head doing this. I usually leave it as a last resort.

many thanks for the fast replies ! If i can do something for you in return let me know, i'm pretty good in ICT

the procedure is the same for a NEW HEAD and for unclogging a head, since the manual mentions this, btw .. what kind of tube do you use ? i got a 2mm but that seems a pretty tight fit

the procedure is the same for a NEW HEAD and for unclogging a head, since the manual mentions this, btw .. what kind of tube do you use ? i got a 2mm but that seems a pretty tight fit

Solventinkjet

DIY Printer Fixing Guide

many thanks for the fast replies ! If i can do something for you in return let me know, i'm pretty good in ICT

the procedure is the same for a NEW HEAD and for unclogging a head, since the manual mentions this, btw .. what kind of tube do you use ? i got a 2mm but that seems a pretty tight fit

View attachment 147294

I use a soft tube that is used in the pumps. Mostly you just want it to clean if you aren't using the damper. Also be careful when pushing the solution through. The tube can pop off and it tends to go straight into your eye! I learned the hard way.

It looks like the damper they are using is a damper that is used in the JV5's (and rolands) with dx5 head, i'll just take on of them and secure it and keep presure on it, the detaching probably occurs when pressure can't get away in the head at the first moment, point of the weakest resistance and bob's your uncle...

ok .. i got the unit finally in my workshop, problem is did a full purge, now the units ask me to configure the inkts ;. SS21 is chosen, the last slot (black) is having issues; it says the cartridge is empty, or expired, or a mix, when i put the same cartridge in slot 7 it detects automatically.

i assume it is a fault in reading the chip? but the chip reads fine in slots 7, slot 8 detection goes haywire, any idea how to solve this one ?

the pump also seems to be leaking, gonna try to flush or replace the tubes, or order a new one

i assume it is a fault in reading the chip? but the chip reads fine in slots 7, slot 8 detection goes haywire, any idea how to solve this one ?

the pump also seems to be leaking, gonna try to flush or replace the tubes, or order a new one

Last edited:

ok .. i got the unit finally in my workshop, problem is did a full purge, now the units ask me to configure the inkts ;. SS21 is chosen, the last slot (black) is having issues; it says the cartridge is empty, or expired, or a mix, when i put the same cartridge in slot 7 it detects automatically.

i assume it is a fault in reading the chip? but the chip reads fine in slots 7, slot 8 detection goes haywire, any idea how to solve this one ?

the pump also seems to be leaking, gonna try to flush or replace the tubes, or order a new one

i skipped this procedure using 119/121 in running parameters

i opened the cartidge house for inspecting slot 8, i notice dthat the tube just falls out of the screw and that it is covered with inkt...