Olly Townsend

New Member

Hi all, totally new here and new to printing

Our company has recently bought a Mimaki CJV30-130 for printing posters etc for our own marketing campaigns!

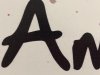

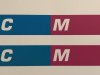

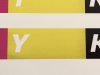

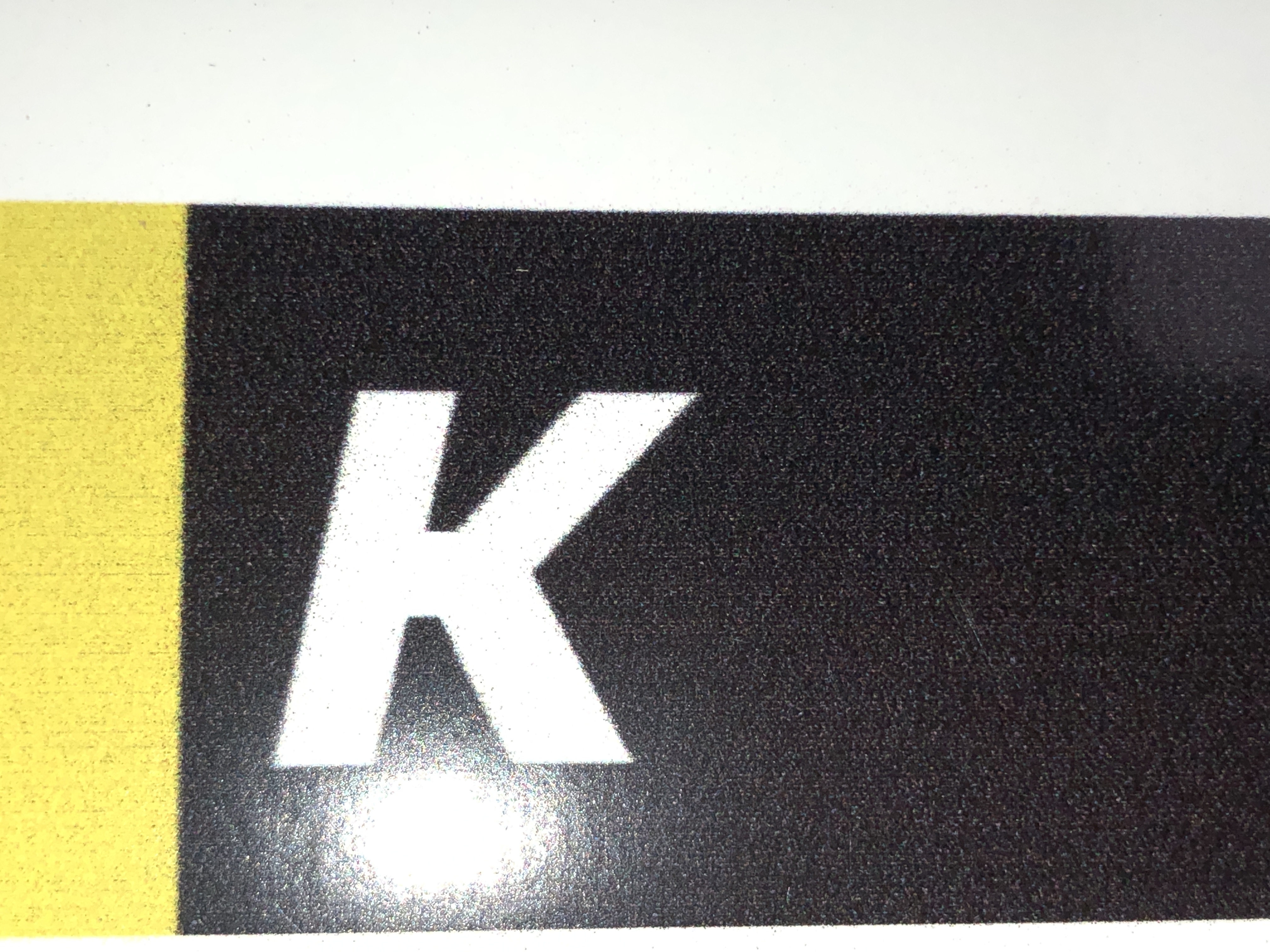

There seems to be some 'over spray' from all colours - this is the best way I can describe it - and also lines in Cyan and Magenta. You can see the over spray most clear on the 'K' pic below

Pics are attached and any help is appreciated?

I have performed many nozzle washes, custody wash, pump tube wash.

Thanks!!

Our company has recently bought a Mimaki CJV30-130 for printing posters etc for our own marketing campaigns!

There seems to be some 'over spray' from all colours - this is the best way I can describe it - and also lines in Cyan and Magenta. You can see the over spray most clear on the 'K' pic below

Pics are attached and any help is appreciated?

I have performed many nozzle washes, custody wash, pump tube wash.

Thanks!!