Andrea_neon

New Member

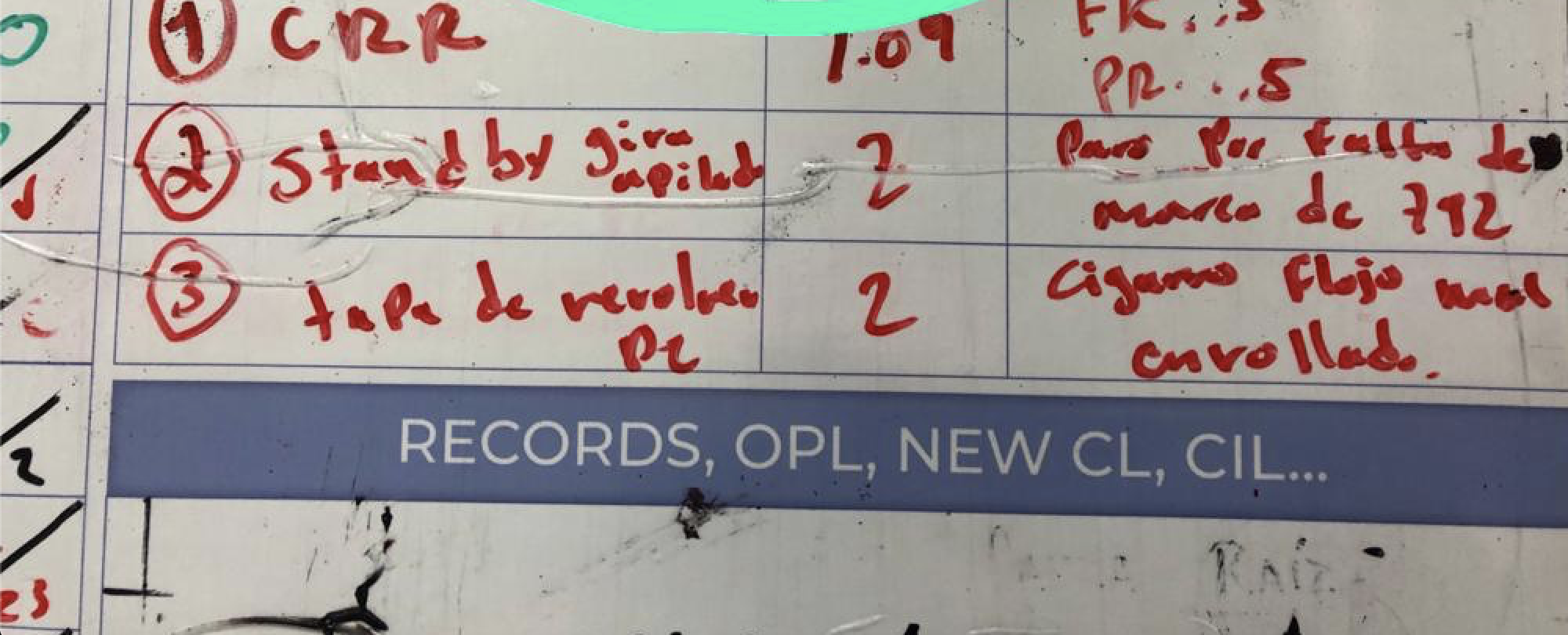

Help! We make a lot of personalized whiteboards by printing the graphics in HP latex 335 and then laminating with Dry Erease laminate 111 from General Formulations. The problem is that 1 out of 3 whiteboards get wrinkles over time, we often use steel or pvc as the rigid material underneath. Mostly the whiteboards are in offices or production sites so they get no direct sunlight.

Someone knows if we are doing something wrong? is it the laminate? Here's a photo

Someone knows if we are doing something wrong? is it the laminate? Here's a photo