xmarksthespot

New Member

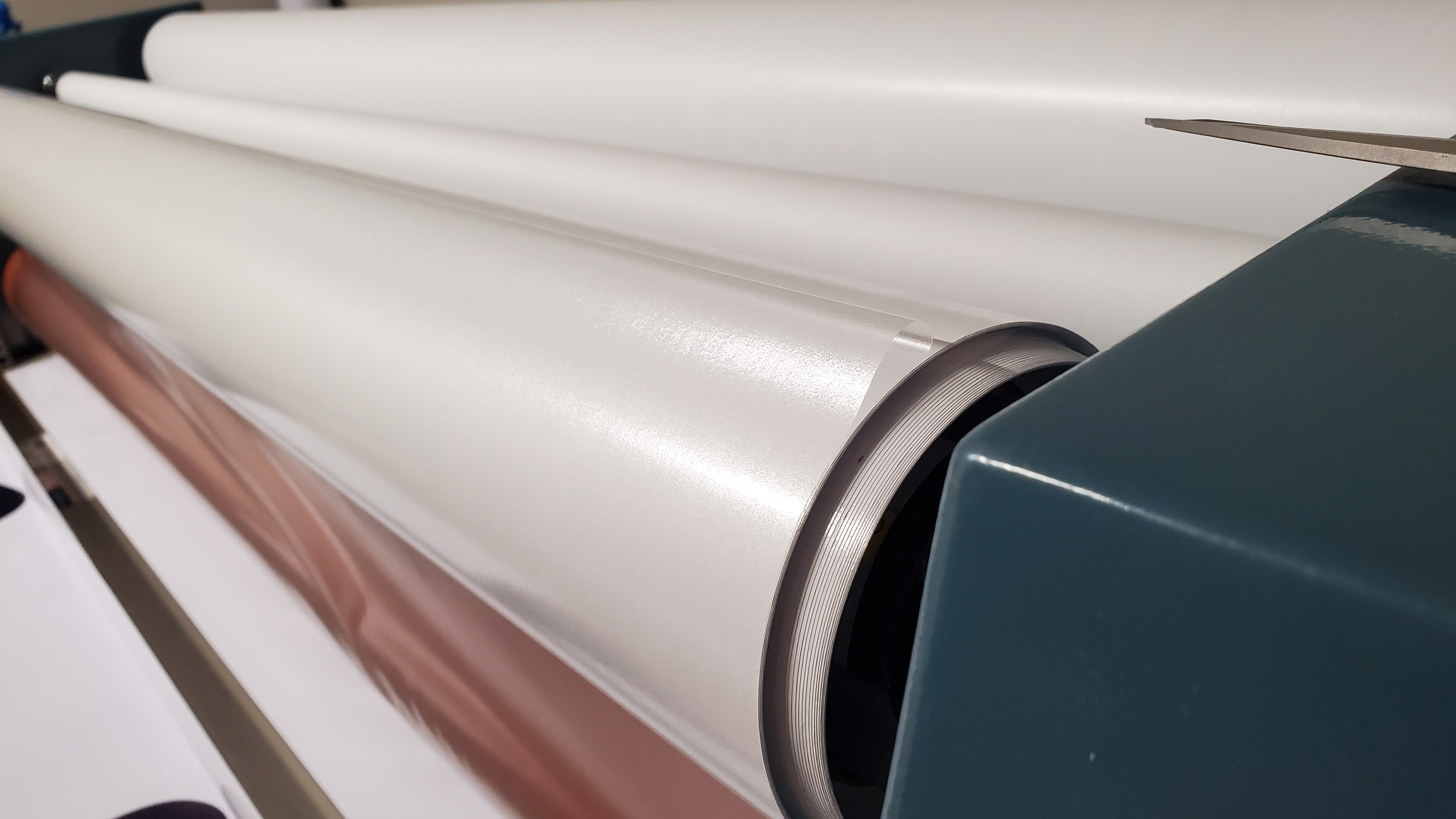

This machine works well enough but if I laminate more than say 6ft of linear material the takeup reel has issues collecting the material fast enough, leading to the problem seen below. By this stage letting things go much longer leads to messy jams. The manual simply says to "set the tension wheels" with no details. Thankfully there have been posts here regarding similar issues, so I've tried a few things...

Based on searching this forum I've tried:

Ensuring all tension wheels are even

All tension wheels are very lightly engaged

All tension wheels with medium engagement (maybe 5 or 6 full turns)

Take up reel has more tension than laminate feed reel

Feed reel has more tension than take up reel

It's clear I'm missing something here. I understand tension will have to be adjusted during takeup to account for changing roll diameters, but I can't even seem to find a baseline. Actually it's not even clear to me what the wheels do exactly. Any help is greatly appreciated, thanks so much!

Based on searching this forum I've tried:

Ensuring all tension wheels are even

All tension wheels are very lightly engaged

All tension wheels with medium engagement (maybe 5 or 6 full turns)

Take up reel has more tension than laminate feed reel

Feed reel has more tension than take up reel

It's clear I'm missing something here. I understand tension will have to be adjusted during takeup to account for changing roll diameters, but I can't even seem to find a baseline. Actually it's not even clear to me what the wheels do exactly. Any help is greatly appreciated, thanks so much!