Hi everyone, is anybody having too much problem with the encoders for these machines?, because I've to change it in a couple of machine every 5-6 months, I try to calibrate it, but I don't know if I'm doing something wrong, somebody told me that these machines are encoder eaters. Please, any suggestion?

-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FB500 Encoders strips eaters?

- Thread starter averias

- Start date

Turnergraphics

New Member

I've changed mine once in 2 years. Still had problems so installed new drive motor and gritted drive pulley

And tightened the belt. I think it was a worn out drive pulley and loose belt the whole time.

And tightened the belt. I think it was a worn out drive pulley and loose belt the whole time.

encoder strip

Never changed one - had FB500 for three years and now an FB750.

How are you cleaning it?

Every 40 hours use (20 with white ink if I remember?) you need to clean the top surface only of the strip -and nothing should be used to clean the underneath where the info is printed - it is very easy to damage the underneath if you clean it too firmly (and NEVER use any cleaning fluid under there especially IPA or PH Flush)

If you don't do regular cleaning it will get dirty to the point where only vigorous cleaning will shift the ink - this is when the damage occurs so clean the strip before it gets too dirty.

Hi everyone, is anybody having too much problem with the encoders for these machines?, because I've to change it in a couple of machine every 5-6 months, I try to calibrate it, but I don't know if I'm doing something wrong, somebody told me that these machines are encoder eaters. Please, any suggestion?

Never changed one - had FB500 for three years and now an FB750.

How are you cleaning it?

Every 40 hours use (20 with white ink if I remember?) you need to clean the top surface only of the strip -and nothing should be used to clean the underneath where the info is printed - it is very easy to damage the underneath if you clean it too firmly (and NEVER use any cleaning fluid under there especially IPA or PH Flush)

If you don't do regular cleaning it will get dirty to the point where only vigorous cleaning will shift the ink - this is when the damage occurs so clean the strip before it gets too dirty.

Hi everyone

Machine is not mine, I guess they use to clean it, I have gone there to Change a couple of times the encoder, it makes me think that I'm doing something wrong, I always clean the glue of the previous foam used to hold the encoder, and try to put the encoder without waves. But this is the third time that I Change the encoder in leas than a year, when I arrive to the customer, he claims about errors during printing and lost pulses encoder errors.

Last time I move the encoder reader to ensure that the strip was in the center, and when I was in the customer place Last week, I realised a little scratch in a very small side of the strip, But most of the strip is ok, most of the Jobs this customer prints are printed in express Outdoor, But the machine is more problematic if he prints in slower printmodes.

A tech friend from france told me that is very complicated to Change the encoder due to the foam, and he told me that this Way to hold the encoder is very problematic for techs.

Anybody has replaced this encoder, and know how to do it correctly?

Thanks

Machine is not mine, I guess they use to clean it, I have gone there to Change a couple of times the encoder, it makes me think that I'm doing something wrong, I always clean the glue of the previous foam used to hold the encoder, and try to put the encoder without waves. But this is the third time that I Change the encoder in leas than a year, when I arrive to the customer, he claims about errors during printing and lost pulses encoder errors.

Last time I move the encoder reader to ensure that the strip was in the center, and when I was in the customer place Last week, I realised a little scratch in a very small side of the strip, But most of the strip is ok, most of the Jobs this customer prints are printed in express Outdoor, But the machine is more problematic if he prints in slower printmodes.

A tech friend from france told me that is very complicated to Change the encoder due to the foam, and he told me that this Way to hold the encoder is very problematic for techs.

Anybody has replaced this encoder, and know how to do it correctly?

Thanks

Turnergraphics

New Member

I don't think your encoder strip is the problem. The encoder strip works correctly as long as it isn't physically damaged. Could be the drive pulley, belt tension, encoder reader etc. It's time to pay for phone tech support and get some trouble shooting guidance.

Turnergraphics

New Member

Did you ever solve the encoder problem on fb500? Recently I've replaced everything except the reader. Still getting pulse errors.

Thank you

Thank you

Turnergraphics

New Member

I discovered today that my encoder strip is wavy because the foam they send with it is wavy. You have to give the foam a little stretch when sticking it on to the bar so that it's flat. Ran the carriage motion test today after new strip , and still getting carriage motion errors. New reader will be next. The sales people don't tell you how much money you'll spend repairing and maintaining this machine.

Olympic Print

1 year experience

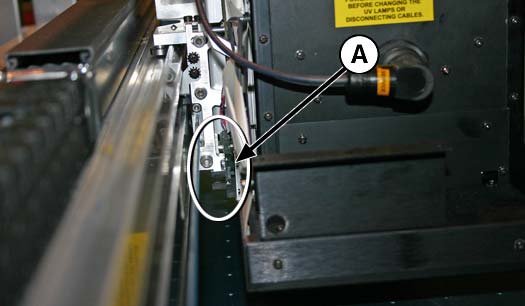

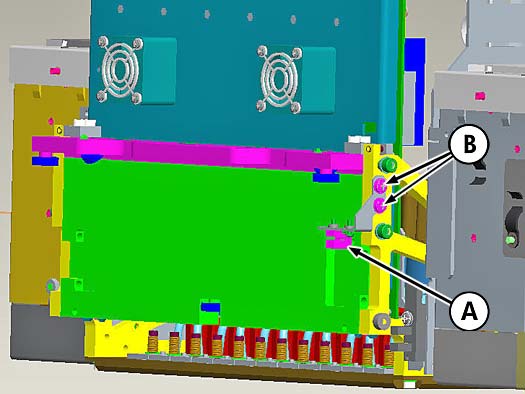

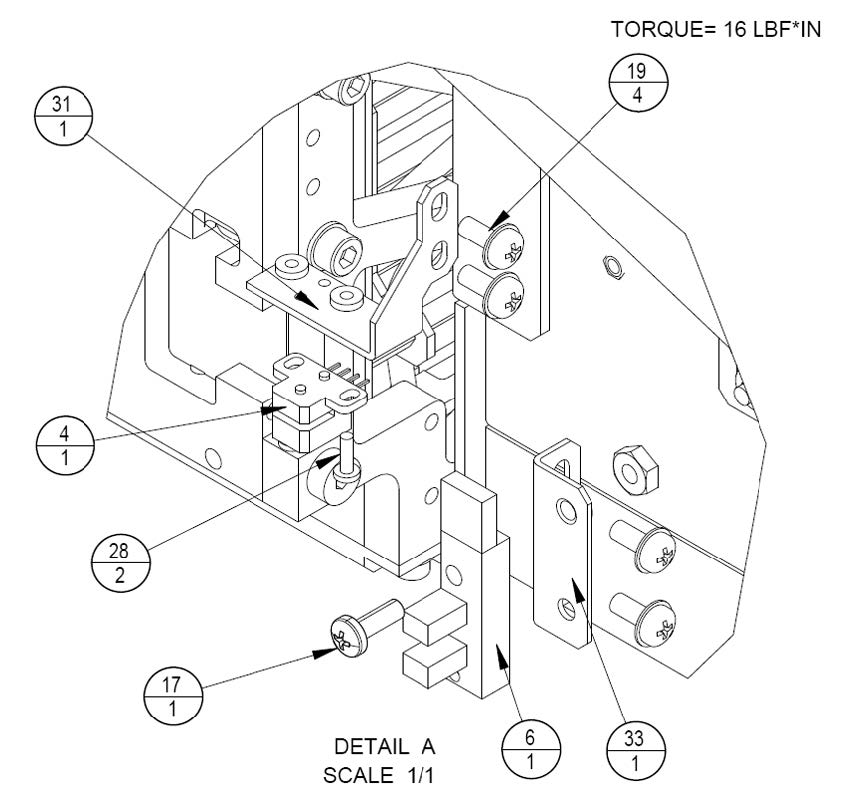

I had been having issues with my encoder strip recently as well. It will stop printing and send the sheets out. I recently read that I could clean the encoder reader with compressed air. I did that and am not having any more problems. Here are some pics.

Thanks to this forum.

Thanks to this forum.