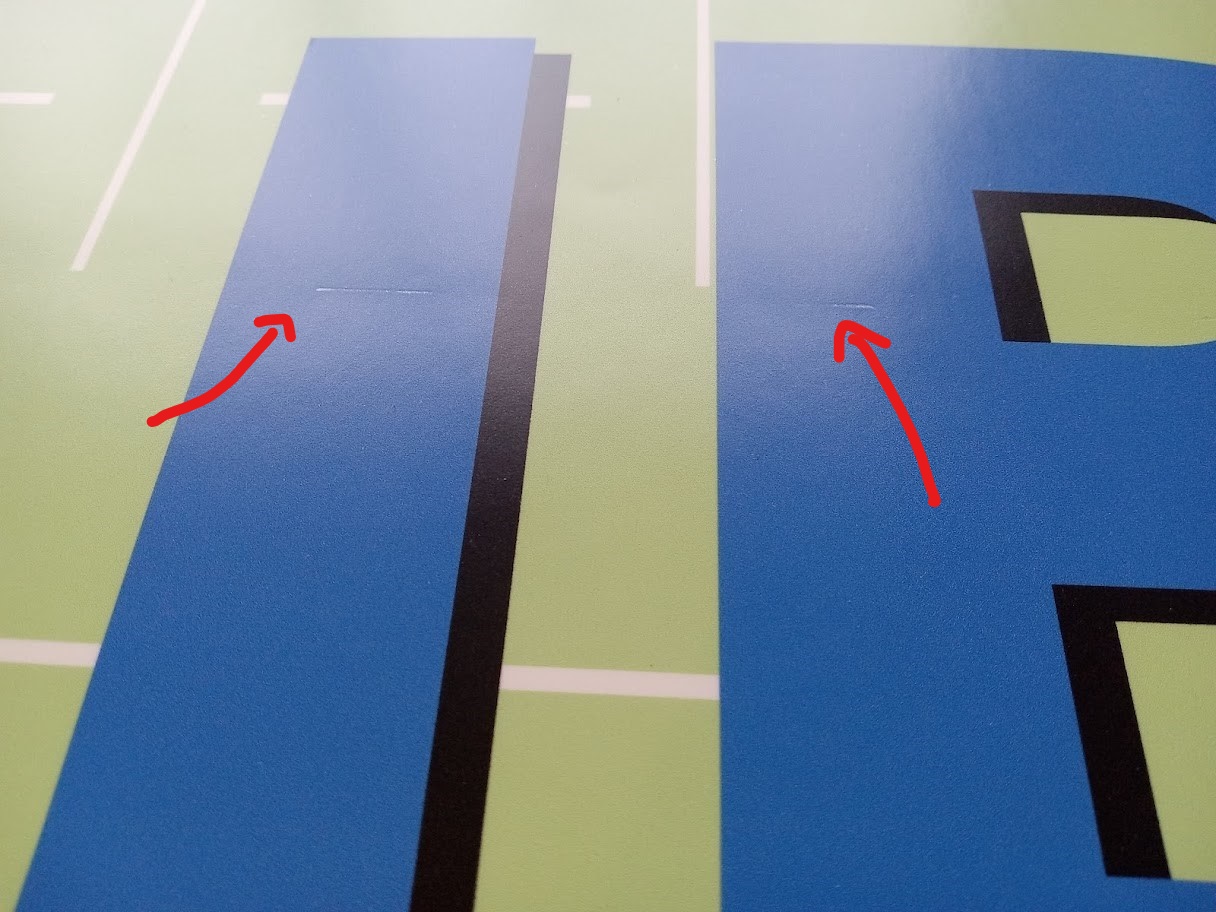

Hello. Occasionally we have been getting these horizontal dashes of what look like indentations/dents in our prints after laminating. They look like laminate bubbles, but they don't appear to have any depth like a bubble would. They don't appear often enough to be too problematic and we don't ever notice them until after laminating, which is why I presume it's something to do with our laminating process. Anybody experience something like this before? We use Oraguard 210 laminate on a Sigmont 55h Royal Sovereign. Here is an attached photo of our issue.

Any help or advice would be greatly appreciated. Thanks.

Any help or advice would be greatly appreciated. Thanks.