wrapwrap

New Member

Using a HP 335, printing Avery V4000 48", Flexi 21

PHOTOS ARE AT THE BOTTOM

Issue #1 Material looks like it melted/flowed from too much heat (Appears on most of the print, not just the middle area as shown in the pic, I was just trying to get a close up.

Issue #2 (Likely connected to #1) The material shifted while printing, obvious under the text "80" "90"

Very limited amount of material to do testing, bought a partial roll.

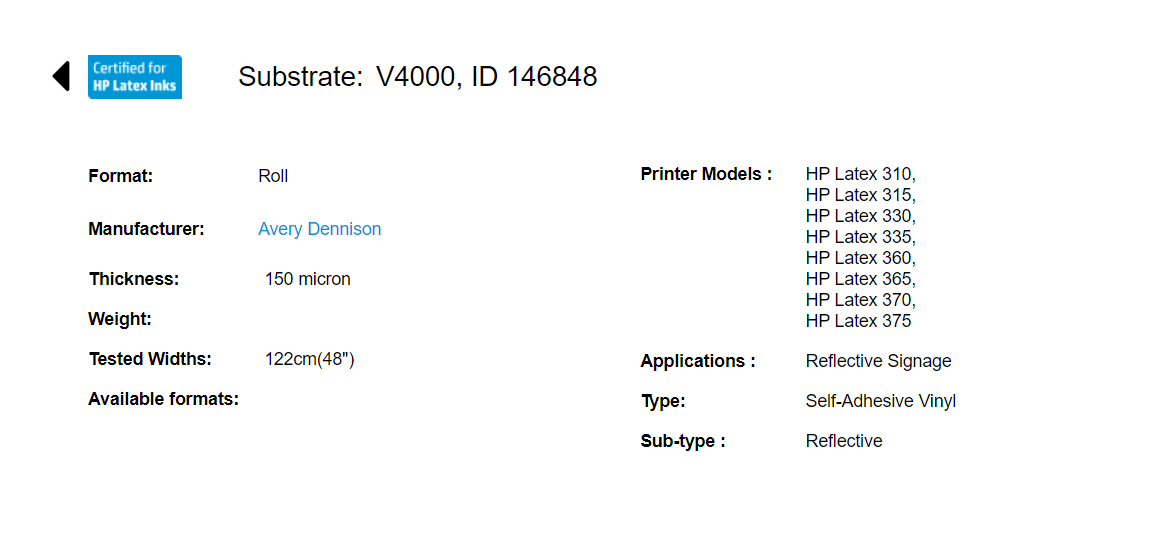

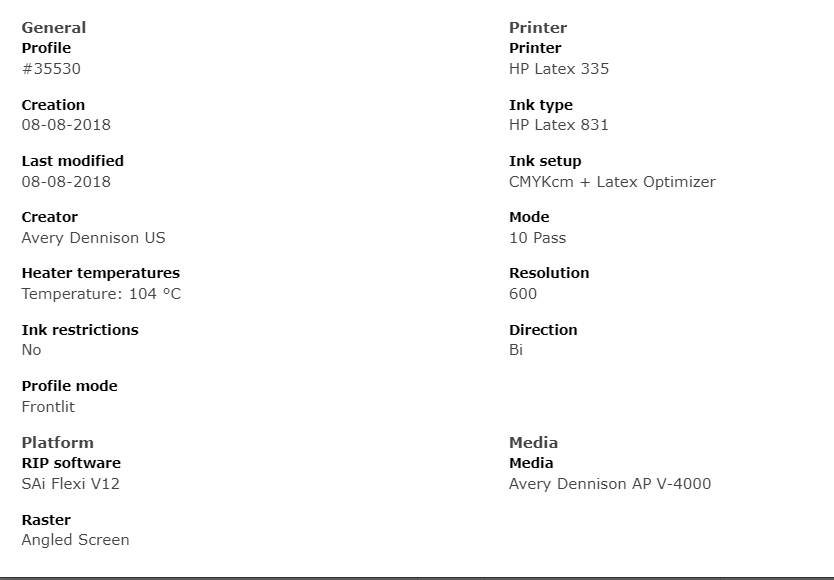

Using the correct profile CERTIFIED for HP Inks (The curing temp is 240F on this profile, 12 Pass)

Now, I just saw on Avery's website that they also have profiles, but none that match my specific setup. Although I cant find a profile on AD website, I do see that all of the V4000 profiles within the HP latex category, have the curing temp set to 104 C /219 F. This obviously supports the thought that the printer was running too hot for this material and caused the melting, but now I am worried to use that HP supplied profile at all because there could be other things wrong if the temp is wrong. Like another weird thing is, HP's profile for this material is 12 or 16 pass, while AD's profile for this material is only 10 pass, (Also at the lower temp). Why are they so different? Should I just run with the HP profile & just bring the temp down to 219? (If you tell me to use the AD profile I am going to be confused because the only available profile for this material, printer, and RIP is for flexi 12, which I run 21 NOT 12. Not even sure if that matters but if I don't know I usually steer clear. AND why is AD profiles only have 10 pass option????)

PHOTOS ARE AT THE BOTTOM

Issue #1 Material looks like it melted/flowed from too much heat (Appears on most of the print, not just the middle area as shown in the pic, I was just trying to get a close up.

Issue #2 (Likely connected to #1) The material shifted while printing, obvious under the text "80" "90"

Very limited amount of material to do testing, bought a partial roll.

Using the correct profile CERTIFIED for HP Inks (The curing temp is 240F on this profile, 12 Pass)

Now, I just saw on Avery's website that they also have profiles, but none that match my specific setup. Although I cant find a profile on AD website, I do see that all of the V4000 profiles within the HP latex category, have the curing temp set to 104 C /219 F. This obviously supports the thought that the printer was running too hot for this material and caused the melting, but now I am worried to use that HP supplied profile at all because there could be other things wrong if the temp is wrong. Like another weird thing is, HP's profile for this material is 12 or 16 pass, while AD's profile for this material is only 10 pass, (Also at the lower temp). Why are they so different? Should I just run with the HP profile & just bring the temp down to 219? (If you tell me to use the AD profile I am going to be confused because the only available profile for this material, printer, and RIP is for flexi 12, which I run 21 NOT 12. Not even sure if that matters but if I don't know I usually steer clear. AND why is AD profiles only have 10 pass option????)

Last edited: