The Sign Depot LLC

New Member

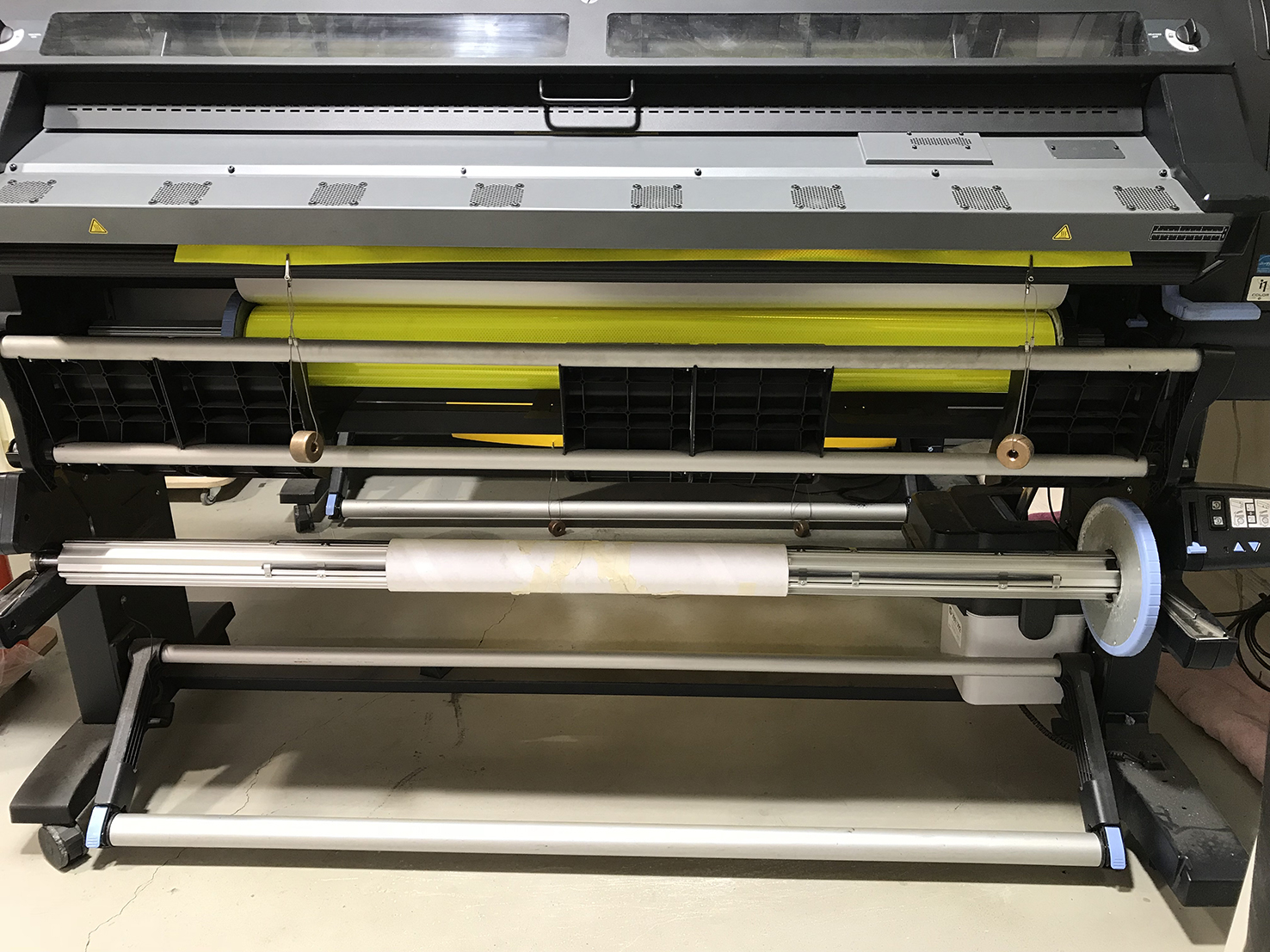

So we just bought our first latex printer, the HP 570. We have a Roland XC540 and a HP FB500 as well.

The problem I have is that almost every time I start a print, the media touches the top heating element, sticks and causes a huge jam. The only reliable way I've found to prevent this is to feed the media to where it just starts to stick out of the heater. But that means I'm wasting about 20 inches of material on every load. Is this normal or am I doing something wrong?

Sent from my SM-N950U using Tapatalk

The problem I have is that almost every time I start a print, the media touches the top heating element, sticks and causes a huge jam. The only reliable way I've found to prevent this is to feed the media to where it just starts to stick out of the heater. But that means I'm wasting about 20 inches of material on every load. Is this normal or am I doing something wrong?

Sent from my SM-N950U using Tapatalk