DPICopy

New Member

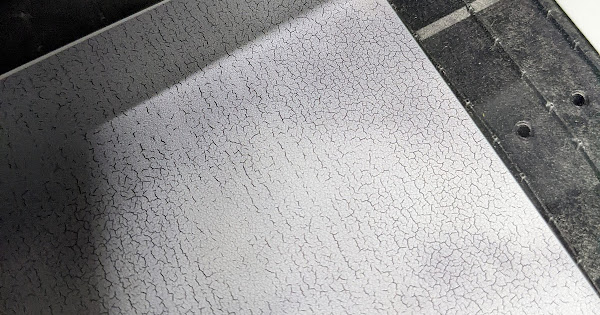

I'm having an issue printing on HP Clear Film. I created a profile using the 'Generic Transparent Polyester Film'. I am trying to print an image with a white under-flood and as the print finishes the ink starts cracking. I have tried taking the curing temp + & - 20 degrees, I also tried dumping the print zone temperature, neither made a difference. I have also printed with and without the take-up reel. It seems to happen at the very end of the printing, it's fine up until the last couple inches then it starts cracking up and down the whole print. It also seems to me more prevalent on the side of the print closest to the maintenance cartridge. Any ideas? More or less optimizer? Could the overcoat play a part?

Profile and pictures attached.

Any help or advice on what to try next would be greatly appreciated!

Happy New Year!

Profile and pictures attached.

Any help or advice on what to try next would be greatly appreciated!

Happy New Year!