Behrmon

Pr. Bear-Mon

Hey all,

Anyone have experience printing glass on an R1000 here?

Here's what I've got:

Printing 18" Sq 1/4 glass backed with White running 31P 100% Den.

Prints are great, detail is good and color is vibrant.

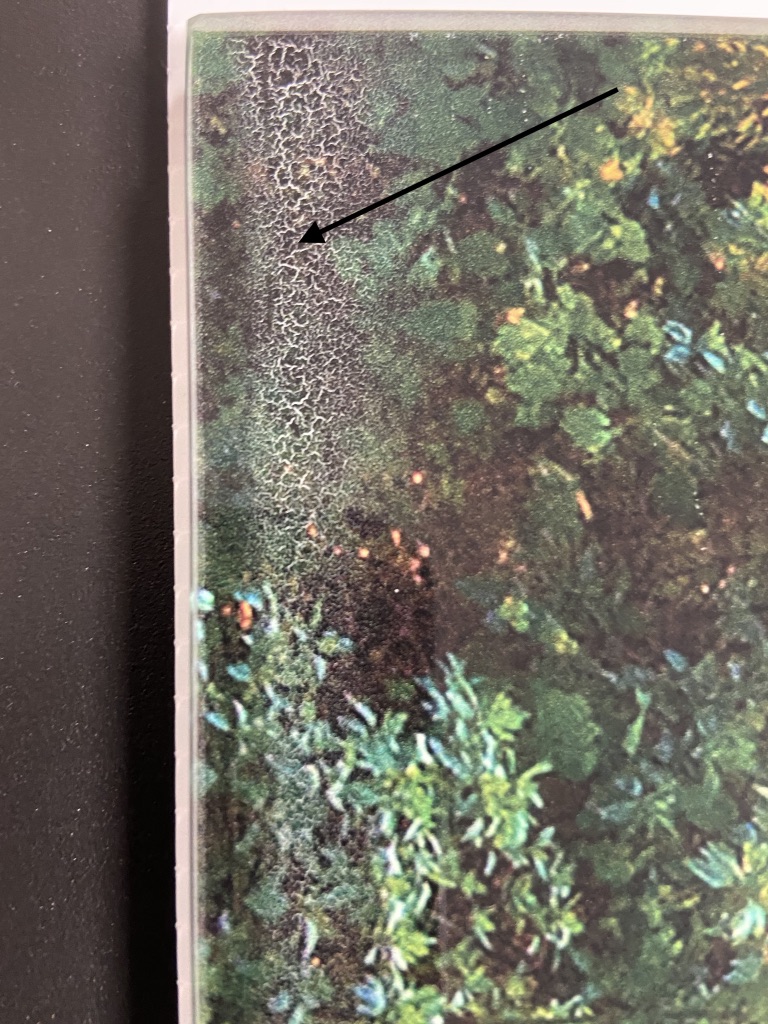

Near the end of the print we get some what appears to be ink coalescence about a 1/4' off the bottom edge then it clears out.

The panel has not exited the heat chamber before this happens.

I've adjusted heat as a test with no affect.

Sorry for the poor pics:

Anyone have experience printing glass on an R1000 here?

Here's what I've got:

Printing 18" Sq 1/4 glass backed with White running 31P 100% Den.

Prints are great, detail is good and color is vibrant.

Near the end of the print we get some what appears to be ink coalescence about a 1/4' off the bottom edge then it clears out.

The panel has not exited the heat chamber before this happens.

I've adjusted heat as a test with no affect.

Sorry for the poor pics: