Windcalmer

The Branding Experts

So my morning has been a fun one. I figured I would share this in case anyone else ends up dead in the water.

On your JV33 printer you have two head lock screws. These are one of the weakest parts know to humankind. They are made of (as best as I can guess) compressed baby powder held together with the tears of a butterfly. They break easy. For the newbies, these are the two screws that you have to loosen in order to change your head height. For the love of the solvent ink gods, DO NOT OVER TIGHTEN THESE SCREWS!

Should you be a mere mortal full of folly and decide to temp fate and tighten them to the point of failure, fear not for there is a quick fix. At least I was able to throw this dirty fix together in about 7.32937 minutes.

Tools you will need:

Small drill bit (3.2 mm or similar)

Small wooden dowel or close approximation. 7mm or greater

Handheld drill or Drill press

Electrical Tape (just there for cleanliness.)

Leatherman Surge is optional if you have a way to cut the dowel.

Washers #10 (I used 3, you may need more or less)

Lastly you will need the actual screw from the end of the head lock screw.

Lets start shall we:

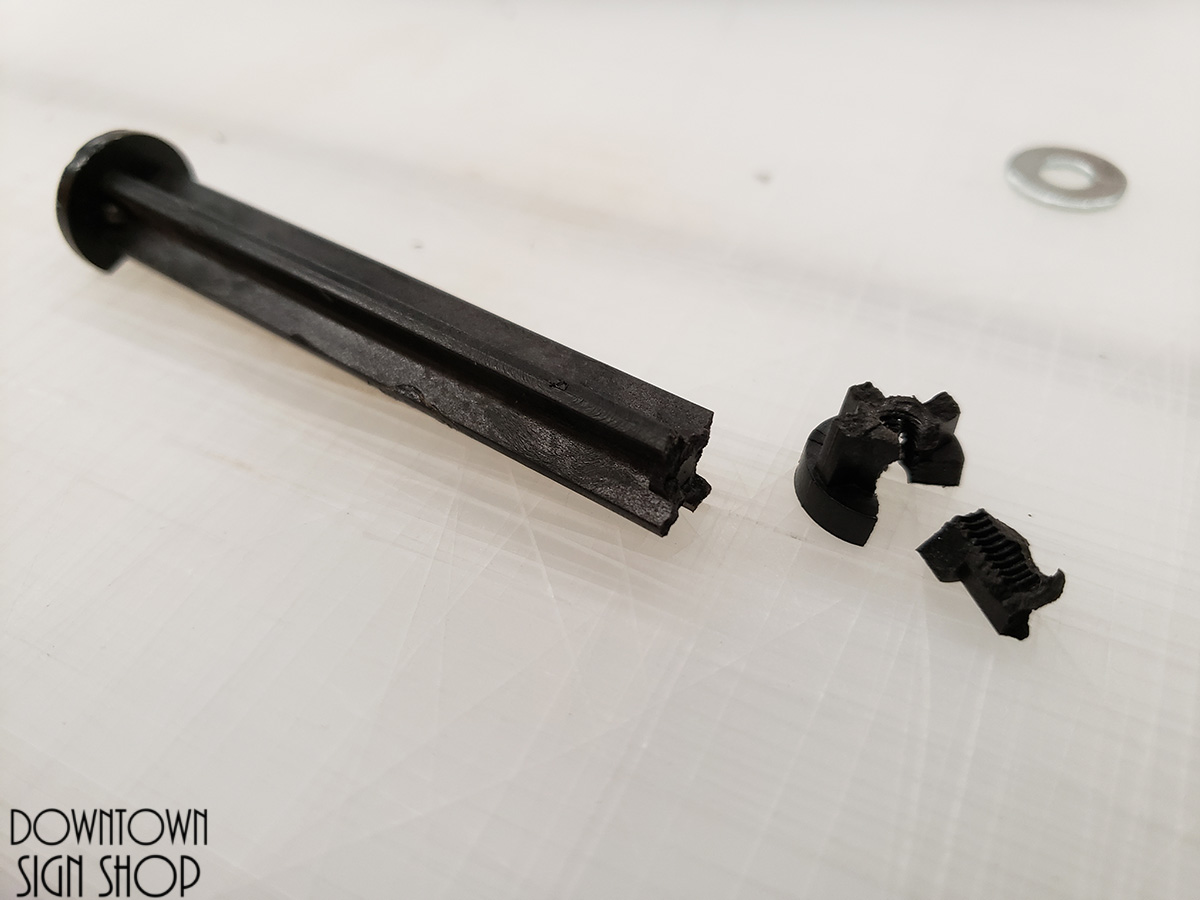

Here we see the head lock screw in all its broken glory. Notice how many points on this failed at one time.

Now, there will be a screw that is still threaded into the back of the head where this long "plastic" shaft came from. Unscrew that screw and whatever you do, do not lose it. We will need that in a few minutes.

Now, take your dowel and cut a length equal to the length of the "plastic" part we broke earlier. Sand or burnish the cut edge to remove loose wood and dust. Use a small piece of tape to remove any dust that may still be on the cut end. Mark the center of the dowel.

I used my Leatherman to cut the paintbrush I used.

Now use small drill bit to drill down into the end of the dowel about 1cm. Wrap the entire length of the dowel in tape and again remove all dust from the dowel.

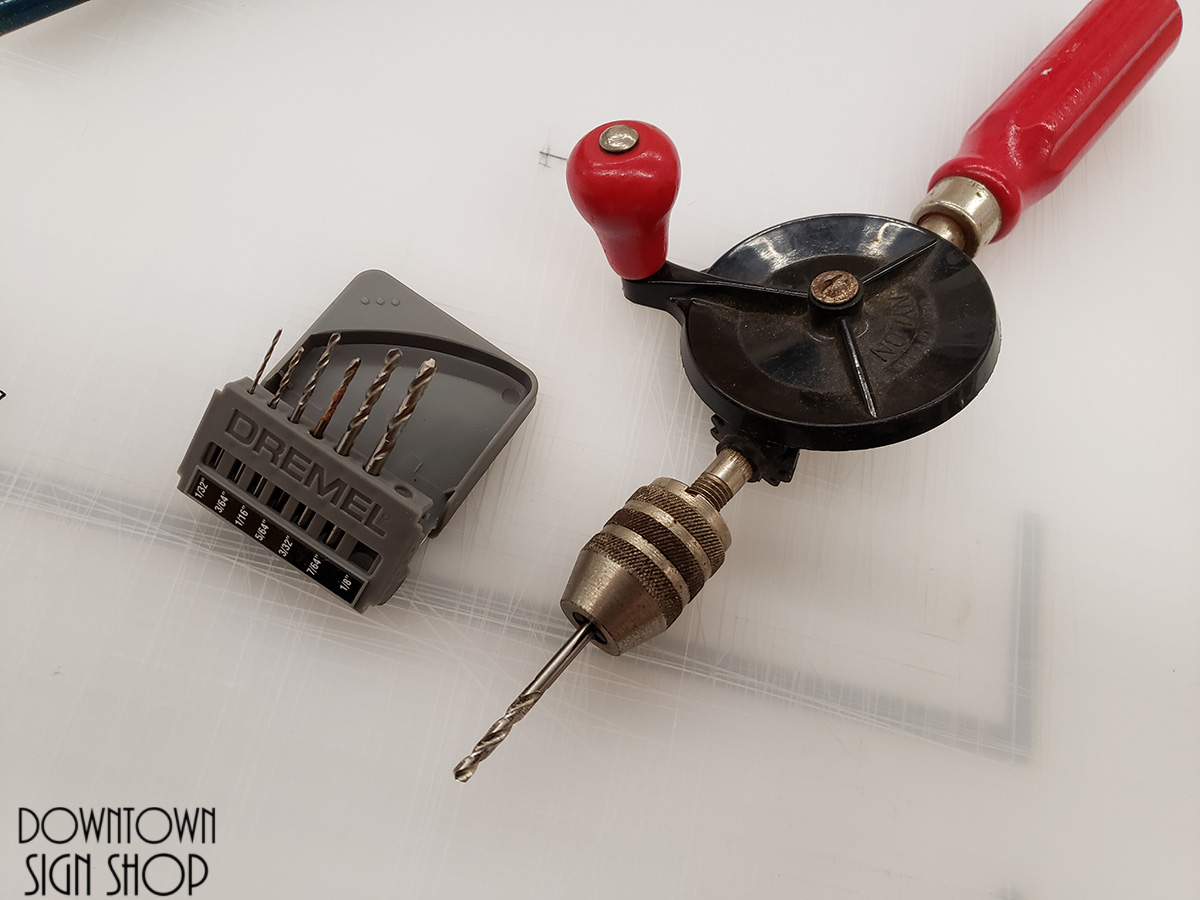

I used a hand held drill and these Dremel bits. The largest bit worked a treat.

Now we have a wooden dowel wrapped in tape with a small screw tightly screwed into the end of it. If not then you may have done something horribly wrong. Go back and find where you took a wrong turn. We will wait for you here.

.

.

.

O.K. Now we are all on the same page. Take your new head lock screw and test fit it into the head. You should have a gap. Now use your washers to make up the gap and tighten by hand. Done.

Congrats! You have completed the equivalent of a 2nd grade art project. Run a cleaning cycle in case you got some dust in your printer, run a test print, and get back to work. We have money to make people!

Yours sarcastically,

Windcalmer

On your JV33 printer you have two head lock screws. These are one of the weakest parts know to humankind. They are made of (as best as I can guess) compressed baby powder held together with the tears of a butterfly. They break easy. For the newbies, these are the two screws that you have to loosen in order to change your head height. For the love of the solvent ink gods, DO NOT OVER TIGHTEN THESE SCREWS!

Should you be a mere mortal full of folly and decide to temp fate and tighten them to the point of failure, fear not for there is a quick fix. At least I was able to throw this dirty fix together in about 7.32937 minutes.

Tools you will need:

Small drill bit (3.2 mm or similar)

Small wooden dowel or close approximation. 7mm or greater

Handheld drill or Drill press

Electrical Tape (just there for cleanliness.)

Leatherman Surge is optional if you have a way to cut the dowel.

Washers #10 (I used 3, you may need more or less)

Lastly you will need the actual screw from the end of the head lock screw.

Lets start shall we:

Here we see the head lock screw in all its broken glory. Notice how many points on this failed at one time.

Now, there will be a screw that is still threaded into the back of the head where this long "plastic" shaft came from. Unscrew that screw and whatever you do, do not lose it. We will need that in a few minutes.

Now, take your dowel and cut a length equal to the length of the "plastic" part we broke earlier. Sand or burnish the cut edge to remove loose wood and dust. Use a small piece of tape to remove any dust that may still be on the cut end. Mark the center of the dowel.

I used my Leatherman to cut the paintbrush I used.

Now use small drill bit to drill down into the end of the dowel about 1cm. Wrap the entire length of the dowel in tape and again remove all dust from the dowel.

I used a hand held drill and these Dremel bits. The largest bit worked a treat.

Now we have a wooden dowel wrapped in tape with a small screw tightly screwed into the end of it. If not then you may have done something horribly wrong. Go back and find where you took a wrong turn. We will wait for you here.

.

.

.

O.K. Now we are all on the same page. Take your new head lock screw and test fit it into the head. You should have a gap. Now use your washers to make up the gap and tighten by hand. Done.

Congrats! You have completed the equivalent of a 2nd grade art project. Run a cleaning cycle in case you got some dust in your printer, run a test print, and get back to work. We have money to make people!

Yours sarcastically,

Windcalmer