jtinker

Owner

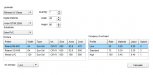

Heyo guys im developing a small applicaton that calculates sign prices and I seem to have hit a brick. I need to know if there is any standard formula that you guys use to calculate the amount of hours worked for a sign when you price it. It will be freeware for desktop browser and smartphones and is in the infancy stages at the moment. But I hope to be completed with it in a month or so.