Pacific Sign

New Member

Hello Everyone!,

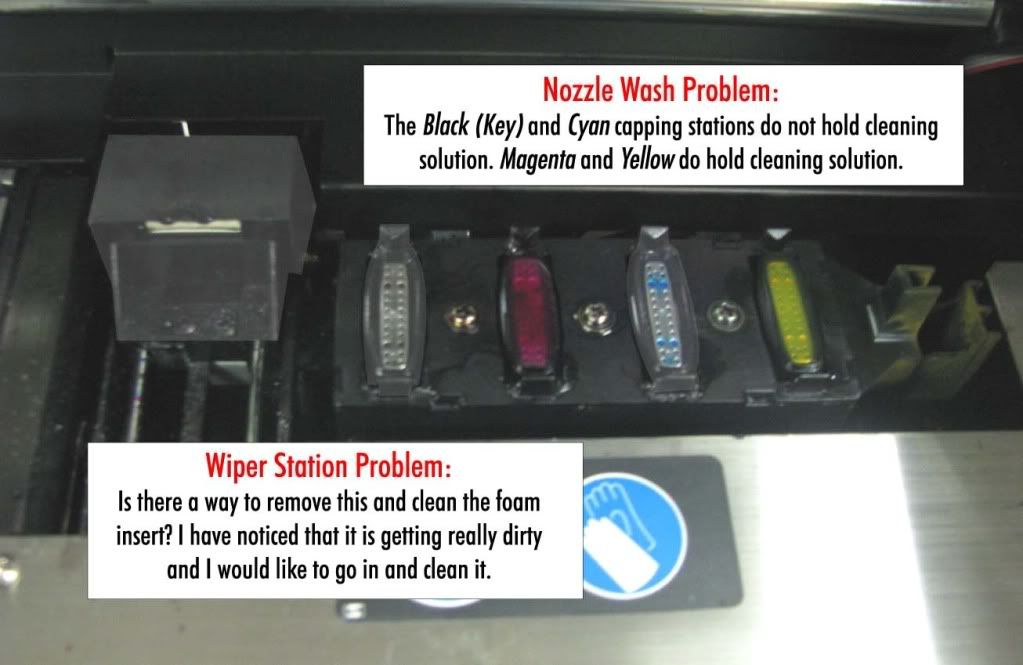

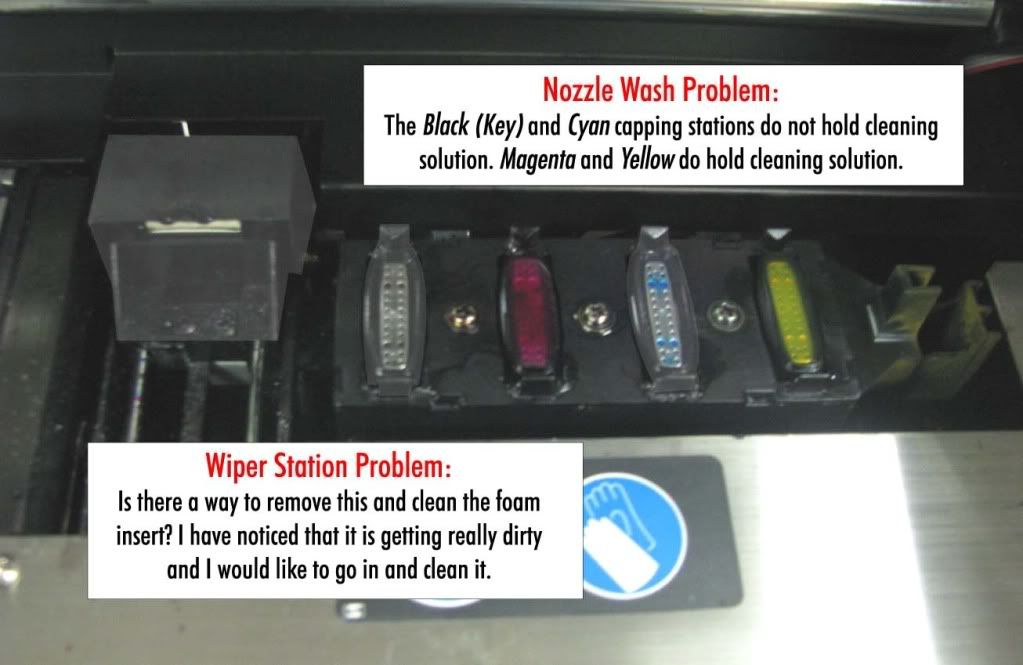

I am having a problem with my Nozzle Wash. I have a Mimaki JV3-160SP. When asked to fill the capping stations with liquid, the Black (Key) and Cyan heads do not hold the cleaning solution. The other ones do. I've included a picture to help visualize my problem.

I was also wondering if there is a way to clean the wiper station, there is a tremendous amount of buildup in this area.

Thanks your help!

I am having a problem with my Nozzle Wash. I have a Mimaki JV3-160SP. When asked to fill the capping stations with liquid, the Black (Key) and Cyan heads do not hold the cleaning solution. The other ones do. I've included a picture to help visualize my problem.

I was also wondering if there is a way to clean the wiper station, there is a tremendous amount of buildup in this area.

Thanks your help!