Coolshrimp

New Member

Hey guy so im just getting into printing I just got a Mimaki CJV30-130.

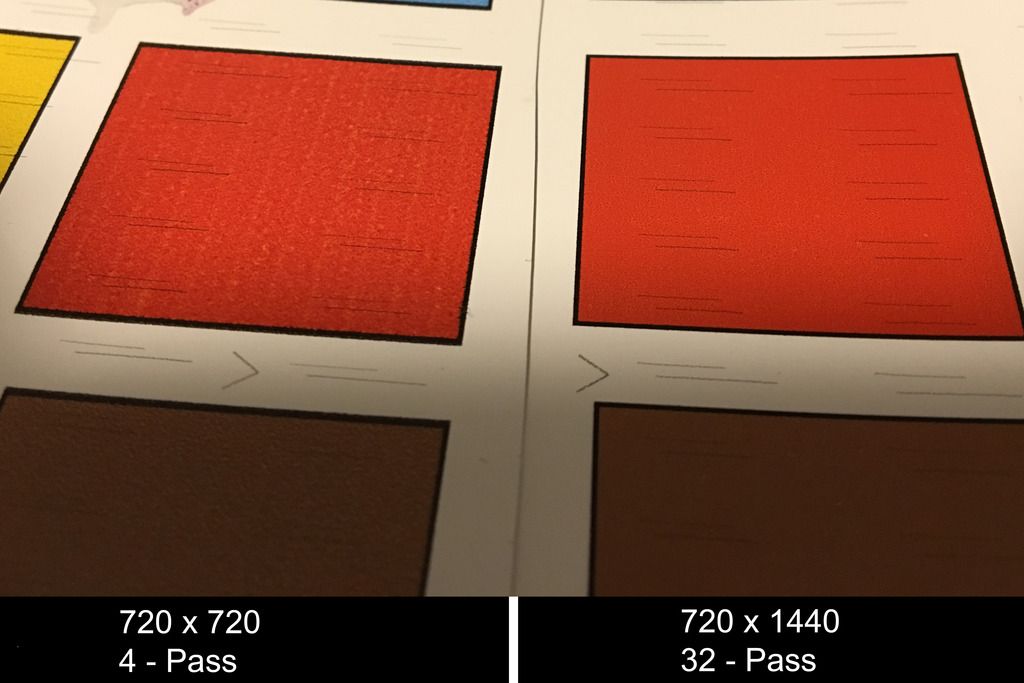

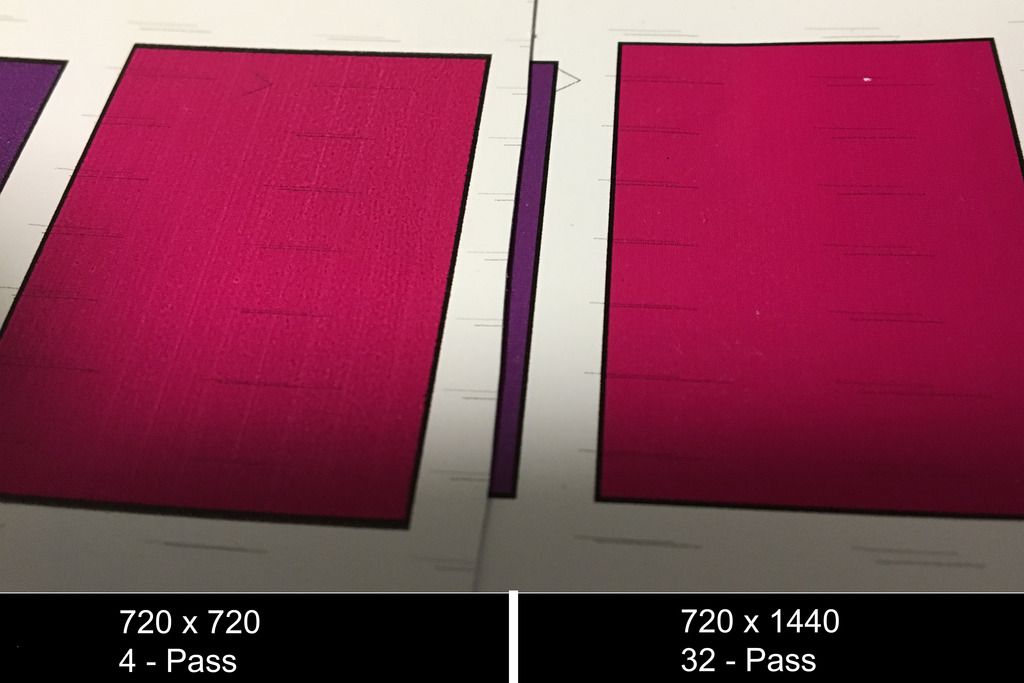

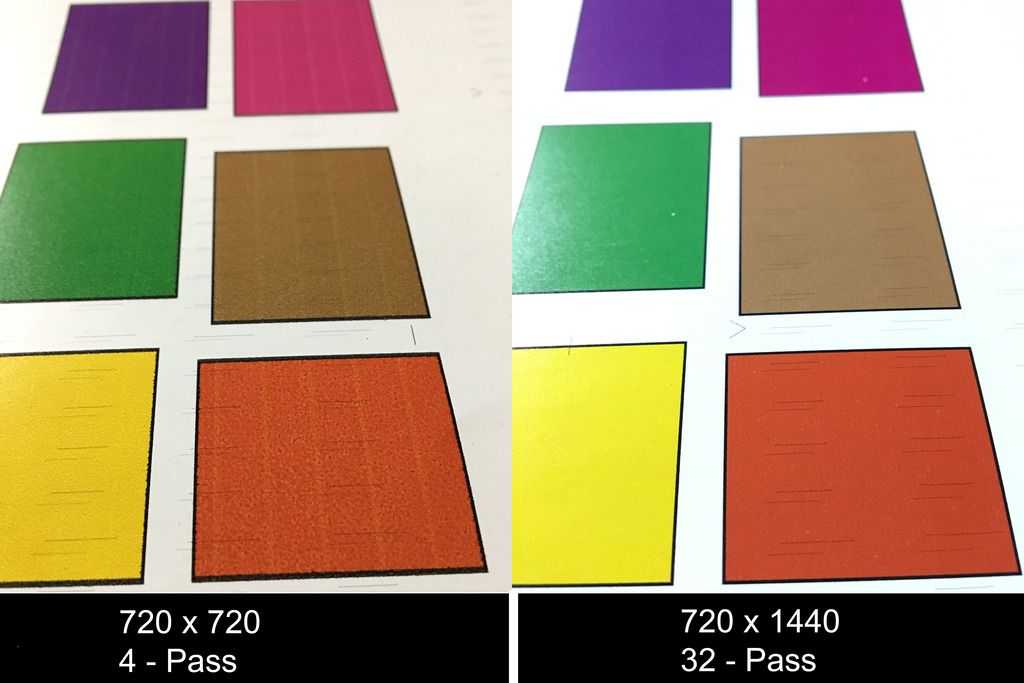

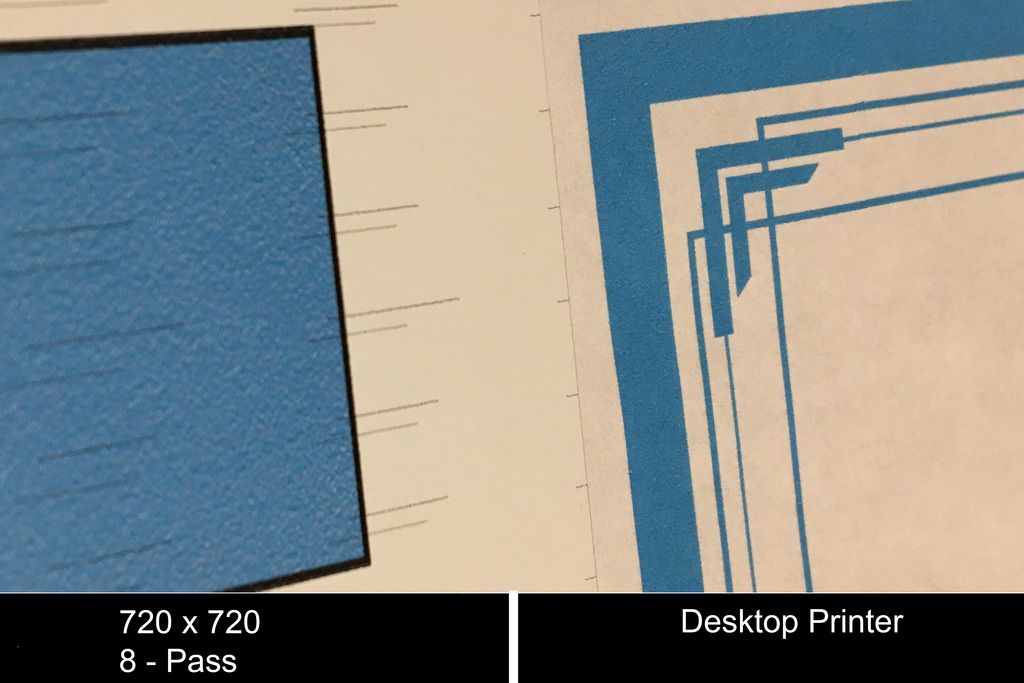

Iv just started using the machine and I notice the printing quality seems low quality.

Seems like there is white grainy spots.

I had the original SS21 Inks and iv just converted to some new ES3 ink.

Originally I didn't know you needed profiles setup and was using the default.

So on the machine in panel setting I have print quality set to fine, and draft also set to fine.

now I believe I got the profiles loaded for my new inks on raster link correctly.

Im set to the highest one (ES3 CMYK 1440 X 720).

I haven't seen any difference at all between prints after changing all those settings.

The image im pringing is not grainy at all on pc even when blown up 300%.

The images are under 12" x 12"

Are these white grainy spots normal? or is this a setting issue?

Thanks.

Here is examples:

http://i102.photobucket.com/albums/m102/coolshrimp/7754DE69-D2CA-4488-9801-6D625A7D11CC.jpg

http://i102.photobucket.com/albums/m102/coolshrimp/2717A420-F903-4358-848D-C7E252F085D3.jpg

Iv just started using the machine and I notice the printing quality seems low quality.

Seems like there is white grainy spots.

I had the original SS21 Inks and iv just converted to some new ES3 ink.

Originally I didn't know you needed profiles setup and was using the default.

So on the machine in panel setting I have print quality set to fine, and draft also set to fine.

now I believe I got the profiles loaded for my new inks on raster link correctly.

Im set to the highest one (ES3 CMYK 1440 X 720).

I haven't seen any difference at all between prints after changing all those settings.

The image im pringing is not grainy at all on pc even when blown up 300%.

The images are under 12" x 12"

Are these white grainy spots normal? or is this a setting issue?

Thanks.

Here is examples:

http://i102.photobucket.com/albums/m102/coolshrimp/7754DE69-D2CA-4488-9801-6D625A7D11CC.jpg

http://i102.photobucket.com/albums/m102/coolshrimp/2717A420-F903-4358-848D-C7E252F085D3.jpg