IvanDD

New Member

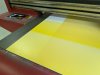

Our yellow now dies out over the course of a print. When I purge the heads with the valves open, I get a steady stream of yellow.

I thought maybe there was some sort of starvation going on but the tanks above the head for yellow seems to be filled fine, since I can drain if I need to. When I do that, I hear the pump kick in the refill the tank. So it sounds like the pump and the tank aren’t the issue.

On the second picture. I paused the print when it started fading. Let it sit for 5 min, and when I resumed it was back to normal. That absolutely sounds like a starvation issue. However after the print finished and the yellow was very faded, I immediately opened the head valve and did a purge and ton of yellow came pouring out of the nozzle. That does not sound like a starvation issue.

I turned the back pressure way down to see if that helped, it did not.

Im stumped.

I thought maybe there was some sort of starvation going on but the tanks above the head for yellow seems to be filled fine, since I can drain if I need to. When I do that, I hear the pump kick in the refill the tank. So it sounds like the pump and the tank aren’t the issue.

On the second picture. I paused the print when it started fading. Let it sit for 5 min, and when I resumed it was back to normal. That absolutely sounds like a starvation issue. However after the print finished and the yellow was very faded, I immediately opened the head valve and did a purge and ton of yellow came pouring out of the nozzle. That does not sound like a starvation issue.

I turned the back pressure way down to see if that helped, it did not.

Im stumped.