I was so happy that hybriddesign sent me a motherboard and other parts including an extra pinch roller. Appreciate him so much.

I went through the process and installed the board, used the Peck tool and eventually replaced a transistor that aparently was blowing fuse 1.

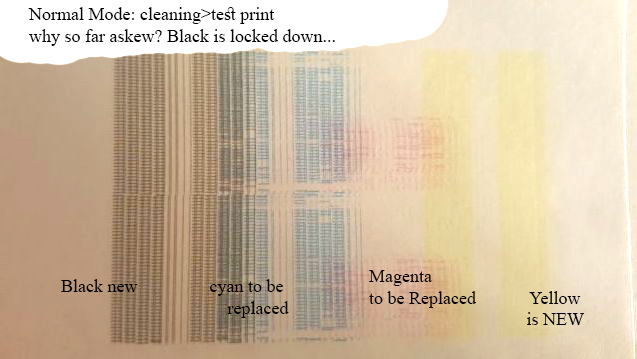

I have just replaced the Black and Yellow heads and they arent stuck "ON" all the time.

The Cyan is not great and the Magenta which was worse is almost non existant even though I kept the heads wet during all this wait time.

I was delayed with a backorder a couple weeks and I hope in the next few days the next two new heads will be here so We can replace the Magenta...... and Cyan if I have to - at this point I am just trying to make headway to get it back to where it WAS printing a while ago.

So using the Service notes I did things like linear calibration, put the 2 head ranks in.

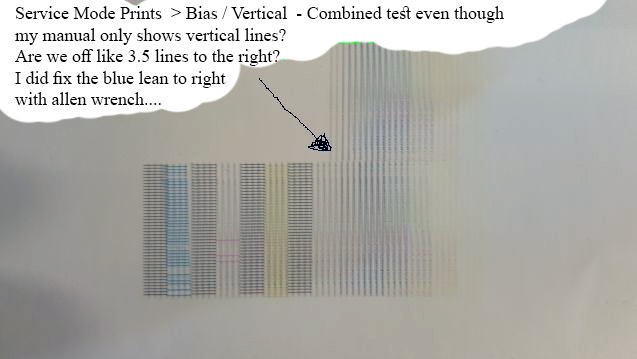

The notes talk about Service mode printing the vertical lines and using small allen wrench to align. And I used a steel ruler to physically line up the heads horizontally.

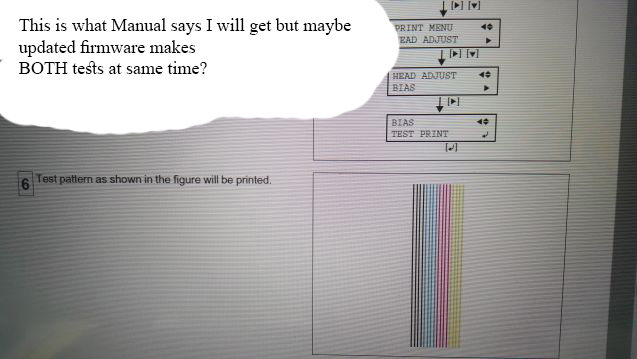

So I know cyan and magenta head needs attention. The manual says vertical print and shows the vertical lines and how to move top lines left or right. The actual test it print looks like it actually is giving both tests at the same time but the lines are 3.5 whole lines offset, the illustration shows solid color bands and mine is printing a grid and it is off SO far that a normal test print has a huge overlap of colors.

Spent HOURS last night doing my best and not seeing any real difference in adjusting the screws except the cyan which was tilted at an angle a little, fixed by the allen wrench.

I guess I gotta rethink if it is possible the carriage board is acting up on me, if the linear tape is acting up -(It calibrates no error) I thought I was doing things in the proper order but nothing looks right and I know how the test prints looked before with color boxes of dashes and now So messed up.

Can anyone tell me if, they think I have the linear problem of an old clear tape (I had cleaned it before all of this happened. I didn't like how it looked so ordered the part, now can't find it) If I have a carrige board problem or somehow I am not doing things in order. I feel pretty beat up over this whole problem and although I am getting there, last night was a total waste and I am not even sure what I would do different.

I will try to post the photos of what panel said, followed by what it printed. I appreciate any suggestions.

And this is what I get:

I went through the process and installed the board, used the Peck tool and eventually replaced a transistor that aparently was blowing fuse 1.

I have just replaced the Black and Yellow heads and they arent stuck "ON" all the time.

The Cyan is not great and the Magenta which was worse is almost non existant even though I kept the heads wet during all this wait time.

I was delayed with a backorder a couple weeks and I hope in the next few days the next two new heads will be here so We can replace the Magenta...... and Cyan if I have to - at this point I am just trying to make headway to get it back to where it WAS printing a while ago.

So using the Service notes I did things like linear calibration, put the 2 head ranks in.

The notes talk about Service mode printing the vertical lines and using small allen wrench to align. And I used a steel ruler to physically line up the heads horizontally.

So I know cyan and magenta head needs attention. The manual says vertical print and shows the vertical lines and how to move top lines left or right. The actual test it print looks like it actually is giving both tests at the same time but the lines are 3.5 whole lines offset, the illustration shows solid color bands and mine is printing a grid and it is off SO far that a normal test print has a huge overlap of colors.

Spent HOURS last night doing my best and not seeing any real difference in adjusting the screws except the cyan which was tilted at an angle a little, fixed by the allen wrench.

I guess I gotta rethink if it is possible the carriage board is acting up on me, if the linear tape is acting up -(It calibrates no error) I thought I was doing things in the proper order but nothing looks right and I know how the test prints looked before with color boxes of dashes and now So messed up.

Can anyone tell me if, they think I have the linear problem of an old clear tape (I had cleaned it before all of this happened. I didn't like how it looked so ordered the part, now can't find it) If I have a carrige board problem or somehow I am not doing things in order. I feel pretty beat up over this whole problem and although I am getting there, last night was a total waste and I am not even sure what I would do different.

I will try to post the photos of what panel said, followed by what it printed. I appreciate any suggestions.

And this is what I get:

Last edited: