Atomic DNA

New Member

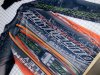

Just wanted to show off a few projects we finished as of late. These are all cut+sew and the materials vary from athletic fleece, boxed mesh jersey material, basic shirt material and regular fleece. All of it is moisture wicking as well. Hope you guys like 'em.

Attachments

-

hoodie2.jpg394.3 KB · Views: 127

hoodie2.jpg394.3 KB · Views: 127 -

hoodieside.jpg352.5 KB · Views: 131

hoodieside.jpg352.5 KB · Views: 131 -

beanies6.jpg659.7 KB · Views: 173

beanies6.jpg659.7 KB · Views: 173 -

beanie3.jpg354.6 KB · Views: 130

beanie3.jpg354.6 KB · Views: 130 -

hoodie1.jpg410.7 KB · Views: 179

hoodie1.jpg410.7 KB · Views: 179 -

beanie2.jpg372.3 KB · Views: 146

beanie2.jpg372.3 KB · Views: 146 -

Ato1.jpg67.9 KB · Views: 149

Ato1.jpg67.9 KB · Views: 149 -

Ato2.jpg68.6 KB · Views: 168

Ato2.jpg68.6 KB · Views: 168 -

Ato3.jpg61.4 KB · Views: 160

Ato3.jpg61.4 KB · Views: 160 -

Ato4.jpg72.8 KB · Views: 160

Ato4.jpg72.8 KB · Views: 160 -

ato5.jpg53.9 KB · Views: 140

ato5.jpg53.9 KB · Views: 140 -

Ato9.jpg67.9 KB · Views: 163

Ato9.jpg67.9 KB · Views: 163 -

Ato8.jpg67.7 KB · Views: 150

Ato8.jpg67.7 KB · Views: 150 -

Ato7.jpg63 KB · Views: 170

Ato7.jpg63 KB · Views: 170 -

Ato6.jpg70.4 KB · Views: 148

Ato6.jpg70.4 KB · Views: 148 -

Ato10.jpg92.3 KB · Views: 136

Ato10.jpg92.3 KB · Views: 136 -

ato11.jpg100.1 KB · Views: 139

ato11.jpg100.1 KB · Views: 139 -

ato12.jpg67.5 KB · Views: 157

ato12.jpg67.5 KB · Views: 157