John Blazy

Dr Dichro

FYI for anyone interested. I added several new laserable laminates to my product line, thus posting here after signing on as merchant. The product is called Dichrolam, and the laminates were developed for high-end commercial trim, inlays, musical instruments, etc, but I see potential in high visual impact signage, trophy, display etc. Its in the higher end of price range, which is why I've stayed away from exhibition display / signage, but production efficiencies have lowered my prices, coupled with ability to mold logos and lettering to expand its utility.

There are three primary product lines:

Molded Textures: molds are made in geometric patterns to form resin-infused laminates with dichroic cores into 3D textured panels like Short Wave, Long Wave, Dune, Bubbles, etc. Used for bar front paneling, exhibition display, column wrap, trophies, etc. "Dune" is in this category, but the molds are random like real sand ripple patterns.

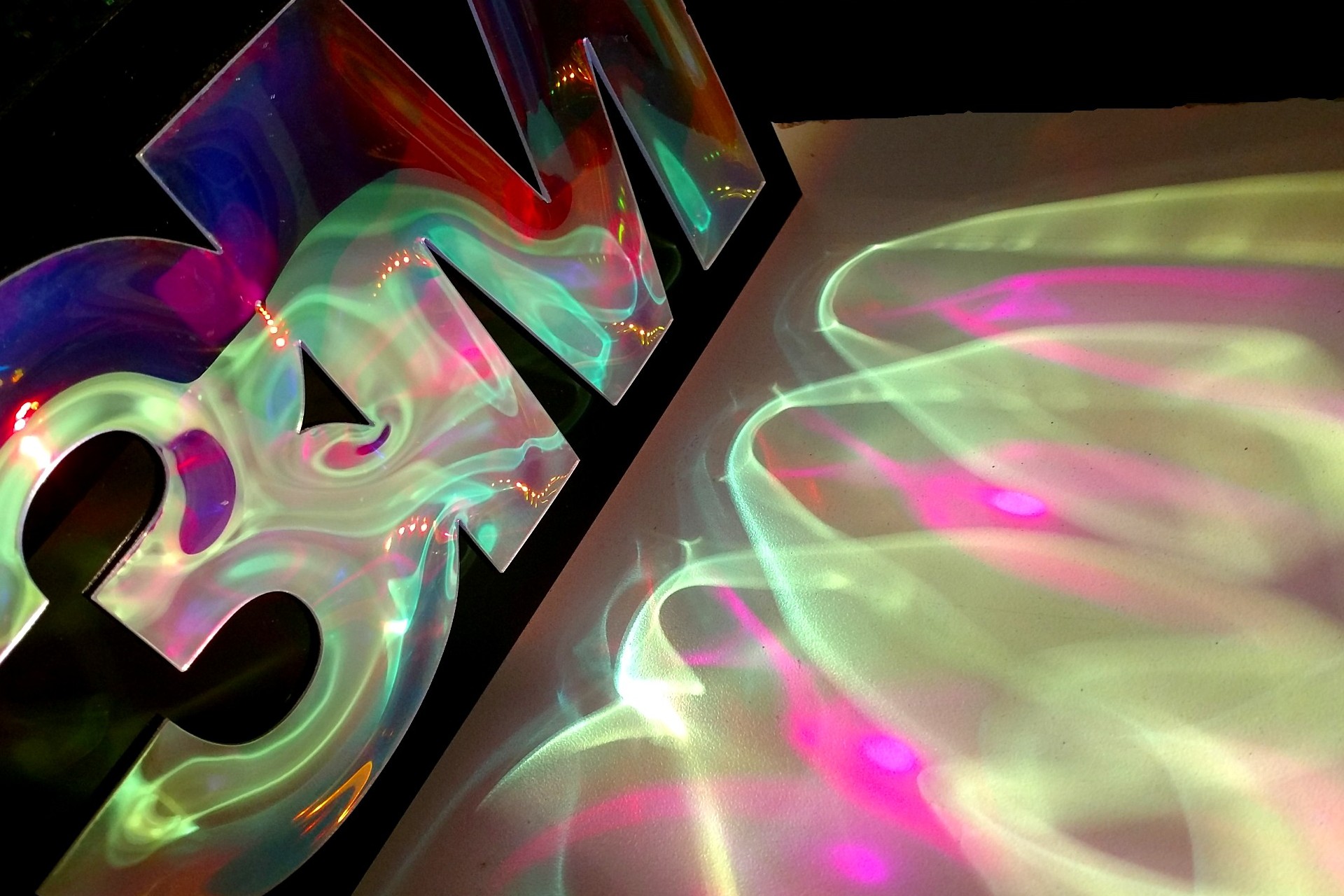

Shape Specific Molded Textures: molds are made according to supplied graphic, logo, or text which then form the resin-infused laminates (with or without) dichroic cores into 3D textured panels that contour to the graphic shape. Signs, Logos, cell phone covers, pickguards etc.

Natural Molded Textures: molds are made to form resin-infused laminates into 3D textured panels to simulate sand ripples or wood figure patterns. Unidirectional carbon fiber is used in the molds to simulate real wood figure with greater chatoyance than actual figured wood.

Burl Textures: No molds used - natural patterning technique developed over 18 years of development (first Dichrolam product). Dichroic fims are hand patterned to bring out 3D texture with color veining in random patterns similar to granite and marble and burled wood. Next post for those pics.

Molded Textures:

Shape Specific Molded Textures:

Natural Molded Textures:

There are three primary product lines:

Molded Textures: molds are made in geometric patterns to form resin-infused laminates with dichroic cores into 3D textured panels like Short Wave, Long Wave, Dune, Bubbles, etc. Used for bar front paneling, exhibition display, column wrap, trophies, etc. "Dune" is in this category, but the molds are random like real sand ripple patterns.

Shape Specific Molded Textures: molds are made according to supplied graphic, logo, or text which then form the resin-infused laminates (with or without) dichroic cores into 3D textured panels that contour to the graphic shape. Signs, Logos, cell phone covers, pickguards etc.

Natural Molded Textures: molds are made to form resin-infused laminates into 3D textured panels to simulate sand ripples or wood figure patterns. Unidirectional carbon fiber is used in the molds to simulate real wood figure with greater chatoyance than actual figured wood.

Burl Textures: No molds used - natural patterning technique developed over 18 years of development (first Dichrolam product). Dichroic fims are hand patterned to bring out 3D texture with color veining in random patterns similar to granite and marble and burled wood. Next post for those pics.

Molded Textures:

Shape Specific Molded Textures:

Natural Molded Textures: