altereddezignz

New Member

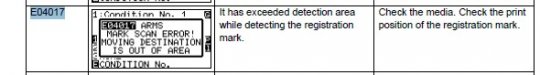

OK so got the printer up and running good but now having all kinds of issues with the arms registration on my plotter.

It is always giving the a out of destination area or scan fail. There has been a couple times that when it will kinda find the first marks then not even be close to the other 3 marks but it will still cut and be way off.

Reg type 2 - reg mark 1"x1" and it is .02 thick. Manual say it can be from .3-1mm or .011-.39".

I have about 4 inches or more in front of the marks and the same behind the marks. I even printed a test page with the reg marks way of the edge of the material. The rollers are not close to the reg marks and it does not matter where i place the cut blade inside the reg marks to start.

It is always giving the a out of destination area or scan fail. There has been a couple times that when it will kinda find the first marks then not even be close to the other 3 marks but it will still cut and be way off.

Reg type 2 - reg mark 1"x1" and it is .02 thick. Manual say it can be from .3-1mm or .011-.39".

I have about 4 inches or more in front of the marks and the same behind the marks. I even printed a test page with the reg marks way of the edge of the material. The rollers are not close to the reg marks and it does not matter where i place the cut blade inside the reg marks to start.