Hello Everyone,

So I wanted to reach out to the community and see if anyone has noticed their normal products failing much sooner than you are used to? Over the past year myself and several other local sign companies I am friends with have been having jobs turn black or dark brown in the light areas. We are located in Florida and have had some brutal heat the last couple of years but this is getting ridiculous. I have been using the same materials for the most part for 10 years now and am very used to how they hold up and what materials can be used for specific purposes.

In general when someone wants a cheap job that only needs to look good for a short time I use a 5 year general formulations vinyl with a intermediate laminate such as 3m 8508. (don't start with the miss matching brands of vinyl and laminate because in most cases it's BS and has no affect.) This product usually lasts 2-3 years outdoors in florida with NO issues but lately I have been having the prints turn black (which I assume is UV damage to the laminate) in as little as 2-3 months!! My bare prints without a laminate last 10 - 20 times longer than that!! I use eco solvent inks. My buddy uses HP latex inks and has 2-3 jobs around me that failed in 3 months as well using a 5 year arlon vinyl and laminate. Another company I know had a job fail in 5 months using 3m ij-40 with 8510 laminate and so have I.

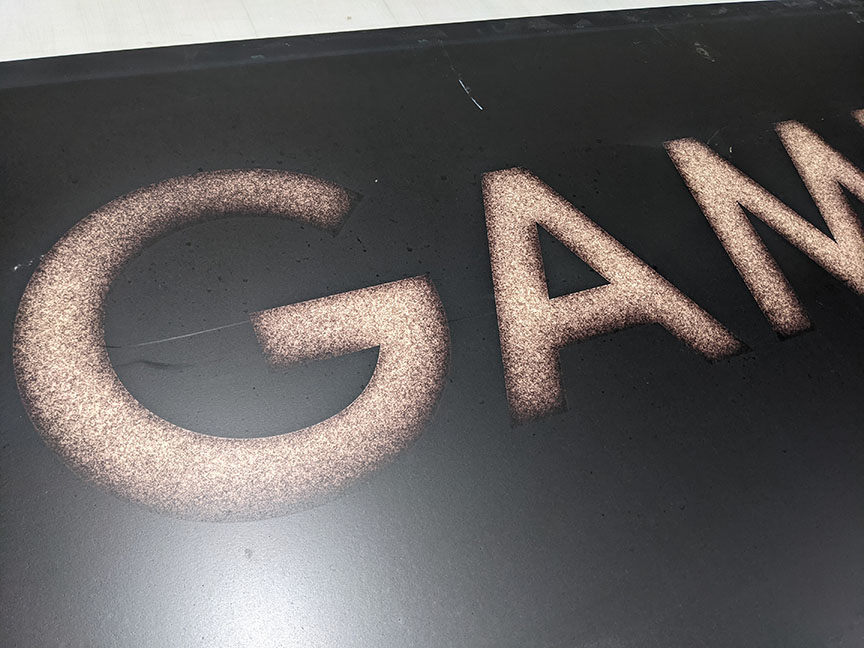

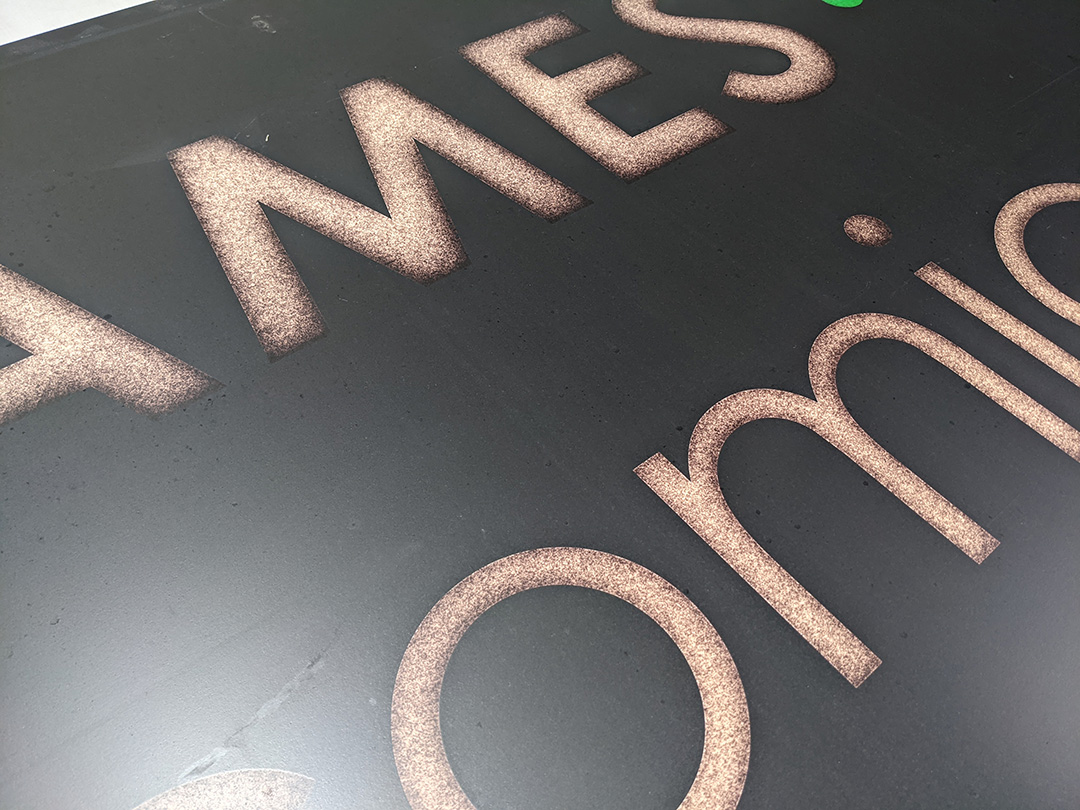

Attached is a photo of a job that is 7 months old. The vinyl is 3m IJ-40 and the laminate is 3m 8510 mounted to aluminum composite. The text should be white. The sign has some yellow and greens as well that also have black / brown haze in them but not as noticeable as the white areas. My assumption is this is UV damage to the laminate or the glue attached to the laminate. The vinyl itself is not turning black because I tore some of it apart until I could separate the layers and the vinyl is fine. These photos are examples of what I have been seeing A LOT lately across many materials and companies. I have been in business for 15 years and in all the years of my repeat customers I have never a call about failures like this until this year.

So I wanted to reach out to the community and see if anyone has noticed their normal products failing much sooner than you are used to? Over the past year myself and several other local sign companies I am friends with have been having jobs turn black or dark brown in the light areas. We are located in Florida and have had some brutal heat the last couple of years but this is getting ridiculous. I have been using the same materials for the most part for 10 years now and am very used to how they hold up and what materials can be used for specific purposes.

In general when someone wants a cheap job that only needs to look good for a short time I use a 5 year general formulations vinyl with a intermediate laminate such as 3m 8508. (don't start with the miss matching brands of vinyl and laminate because in most cases it's BS and has no affect.) This product usually lasts 2-3 years outdoors in florida with NO issues but lately I have been having the prints turn black (which I assume is UV damage to the laminate) in as little as 2-3 months!! My bare prints without a laminate last 10 - 20 times longer than that!! I use eco solvent inks. My buddy uses HP latex inks and has 2-3 jobs around me that failed in 3 months as well using a 5 year arlon vinyl and laminate. Another company I know had a job fail in 5 months using 3m ij-40 with 8510 laminate and so have I.

Attached is a photo of a job that is 7 months old. The vinyl is 3m IJ-40 and the laminate is 3m 8510 mounted to aluminum composite. The text should be white. The sign has some yellow and greens as well that also have black / brown haze in them but not as noticeable as the white areas. My assumption is this is UV damage to the laminate or the glue attached to the laminate. The vinyl itself is not turning black because I tore some of it apart until I could separate the layers and the vinyl is fine. These photos are examples of what I have been seeing A LOT lately across many materials and companies. I have been in business for 15 years and in all the years of my repeat customers I have never a call about failures like this until this year.