Stacey K

I like making signs

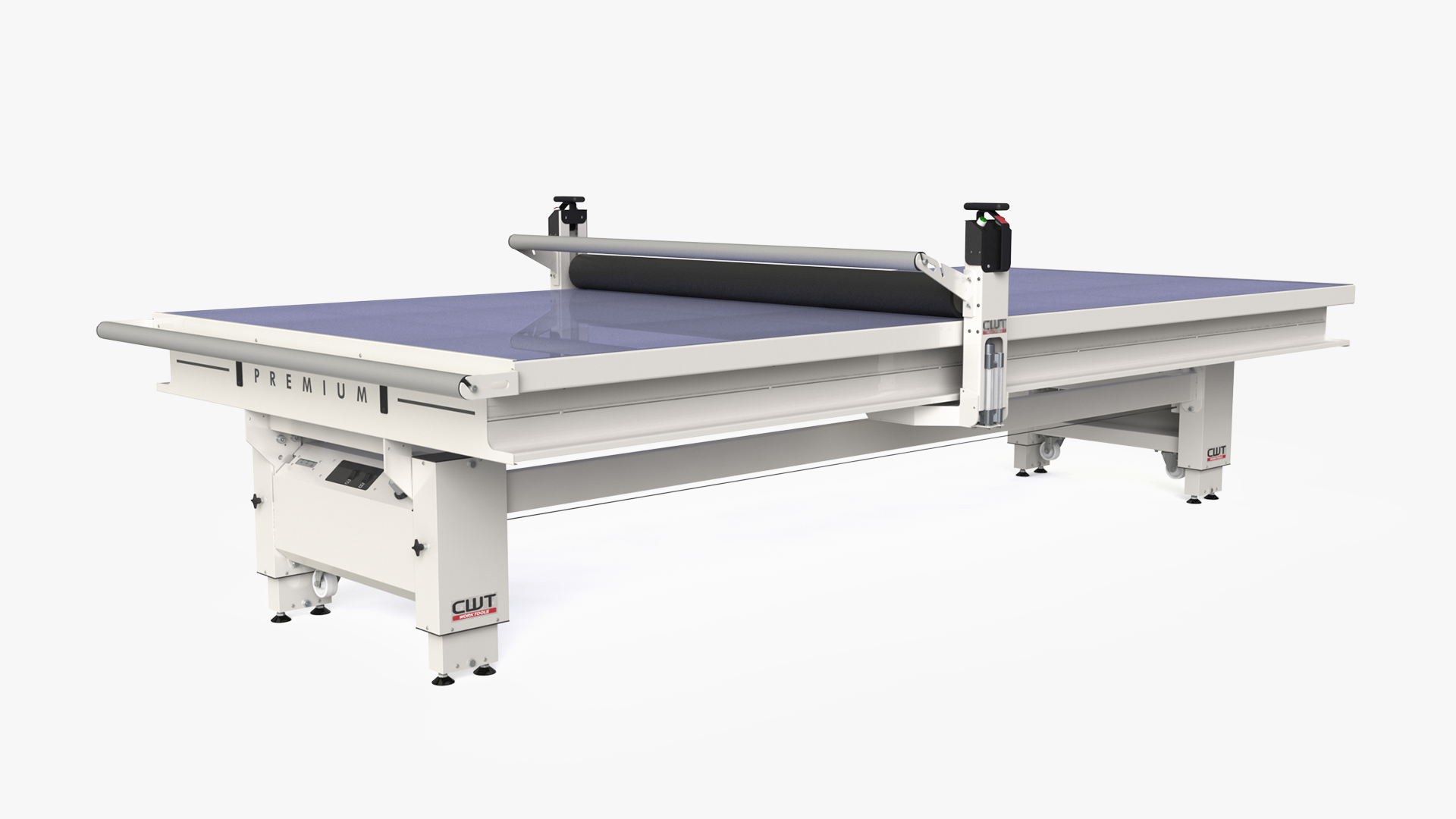

Here's my set-up...roll of 24 or 30" on the end of my table and I use the big squeegee to apply application tape. I have my laminator on the side at the other end and I put a 4'x8' sheet balanced on a large garbage can and roll it through onto that separate table in the bottom of the picture that I can pull closer. It works pretty well.