-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Attaching 6mm ACM

- Thread starter 3Dsigns

- Start date

Johnny Best

Active Member

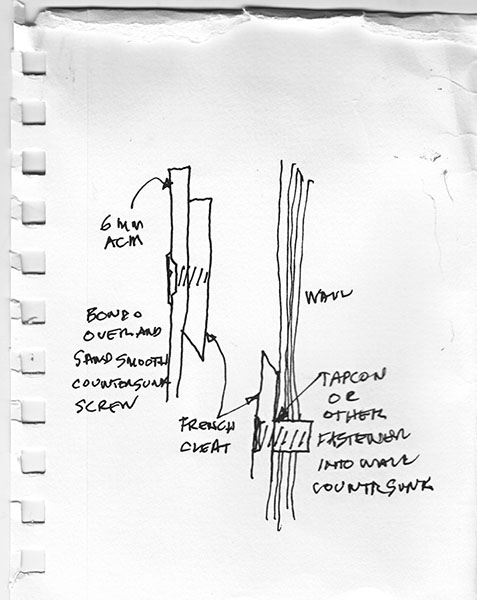

French cleats.

What is the best way to attach a 4x5 shape, cut out of 6mm ACM, onto an outside wall without fasteners showing on the front? If there is a way. Thanks

Can it be stood off the wall at all?

If so, you can make yourself some french cleats out of 1/2" PVC or MDO about 4" tall x 4' long each half piece. Attach the sign side ones with VHB, LEXEL and some really short sheet metal screws that won't penetrate through the face of the sign. You'll need to countersink the screw holes and use flat head screws so figure that into your screw length calculations. Don't skimp on the VHB, LEXEL and screws.

Figure out where the wall side pieces should be mounted and anchor them to the wall making sure you're level and the distance between the two match the gap on the ones on the sign. Same deal on the countersinking.

When you go install the sign over the cleats, squirt a bead of LEXEL along the angled edges of the cleats and it will bond once the weight of the sign compresses everything together.

Something like this.

Attachments

The best way is to purposely show the fasteners by using standoffs.

We have also done this (though it doesn't end up flush mounted) by screwing another material to the wall (indoors we use MDF, outdoors either aluminum blocks or another piece of ACM or thick PVC) and using either VHB tape or another adhesive to install the sign. Downside is that you have to destroy the sign to remove it.

French cleats are another obvious method, though with ACM it's not quite as great a method as it was when we made the signs out of MDO.

We have also done this (though it doesn't end up flush mounted) by screwing another material to the wall (indoors we use MDF, outdoors either aluminum blocks or another piece of ACM or thick PVC) and using either VHB tape or another adhesive to install the sign. Downside is that you have to destroy the sign to remove it.

French cleats are another obvious method, though with ACM it's not quite as great a method as it was when we made the signs out of MDO.

Johnny Best

Active Member

Or you can buy these...

https://www.panelclip.com/

https://www.panelclip.com/

3Dsigns

New Member

Can it be stood off the wall at all?

If so, you can make yourself some french cleats out of 1/2" PVC or MDO about 4" tall x 4' long each half piece. Attach the sign side ones with VHB, LEXEL and some really short sheet metal screws that won't penetrate through the face of the sign. You'll need to countersink the screw holes and use flat head screws so figure that into your screw length calculations. Don't skimp on the VHB, LEXEL and screws.

Figure out where the wall side pieces should be mounted and anchor them to the wall making sure you're level and the distance between the two match the gap on the ones on the sign. Same deal on the countersinking.

When you go install the sign over the cleats, squirt a bead of LEXEL along the angled edges of the cleats and it will bond once the weight of the sign compresses everything together.

Something like this.

Is this the correct Lexel? https://www.lowes.com/pd/Lexel-10-5-fl-oz-Clear-Paintable-Solvent-Caulk/4714985

3Dsigns

New Member

stuccoWhat kinda wall and how high in the air is it ??

Is this the correct Lexel? https://www.lowes.com/pd/Lexel-10-5-fl-oz-Clear-Paintable-Solvent-Caulk/4714985

That's the stuff. We use it for a variety of uses, but mostly for studded dimensional letters and as a secondary adhesive with VHB and screws. I like the consistency of it better than silicone.

Due to the thinness of 6mm ACM, I'm thinking of just going with 12 or 19mm PVC. I could glue PVC standoffs tot he back, screw in some stainless screws and use those as studs. drill holes in the wall [stucco], fill holes with silicone and push in the studs. What do you think?

I think that's a pretty heavy panel to trust glue and silicone with. How custom of a shape is it?

Unless those studs are going 3-4 inches back into the wall and you make really big blocks for your standoffs so they distribute more of the sheer off the weight, I'd be a little nervous about it.

Texas_Signmaker

Very Active Signmaker

I'm not feeling any of these ideas...

I actually just replaced a bunch of Dr nameplates on a hospital's monument sign yesterday...made of stucco and they had what seemed like 5/16" thick 1'x 4' aluminum blanks with the studs screwed into the backs. The studs were then mounted into the stucco and adhesive behind the aluminum. I actually pulled them off and redid them in ACM with 6 painted screws through the face. The hospital didn't want to spend $3k more for using the thick aluminum just to hide the fasteners... I agreed.

I also did a sign last year that was set up with french cleats, 2' x 6' or 7' I think, and it too was like 5/16" thick aluminum with the studs screwed into it from the back. That thing was SUPER heavy.. I myself couldn't lift it 4' on the wall into place without help.

I'm guessing they use solid aluminum because ACM wouldn't allow the studs to securely screw into the back and neither manufacture wanted to risk gluing something. At least doing it this way was a 100% sure fire way that everything is mechanically fastened together and not relying on adhesive. These were both from huge national sign companies serving large large customers, so I assume they have a reason why they do it this way.

I actually just replaced a bunch of Dr nameplates on a hospital's monument sign yesterday...made of stucco and they had what seemed like 5/16" thick 1'x 4' aluminum blanks with the studs screwed into the backs. The studs were then mounted into the stucco and adhesive behind the aluminum. I actually pulled them off and redid them in ACM with 6 painted screws through the face. The hospital didn't want to spend $3k more for using the thick aluminum just to hide the fasteners... I agreed.

I also did a sign last year that was set up with french cleats, 2' x 6' or 7' I think, and it too was like 5/16" thick aluminum with the studs screwed into it from the back. That thing was SUPER heavy.. I myself couldn't lift it 4' on the wall into place without help.

I'm guessing they use solid aluminum because ACM wouldn't allow the studs to securely screw into the back and neither manufacture wanted to risk gluing something. At least doing it this way was a 100% sure fire way that everything is mechanically fastened together and not relying on adhesive. These were both from huge national sign companies serving large large customers, so I assume they have a reason why they do it this way.

Last edited:

Evan Gillette

New Member

Any of you ever use the button fix system before? Its a neat panel mounting system from across the pond.

https://button-fix.com/

I am not sure I would trust them outdoors for a long term install but they have signage examples on their website and lots of loading and testing data. I came across them when getting standoffs from MBS. Caught my attention so I ordered a few pieces of each style to play with, still haven't used them yet (I always forget I have them).

I agree that alumalite would be a better substrate option for the application. I also agree that painted screws would be far easier, cheaper and give more peace of mind. They really aren't noticeable to most people.

https://button-fix.com/

I am not sure I would trust them outdoors for a long term install but they have signage examples on their website and lots of loading and testing data. I came across them when getting standoffs from MBS. Caught my attention so I ordered a few pieces of each style to play with, still haven't used them yet (I always forget I have them).

I agree that alumalite would be a better substrate option for the application. I also agree that painted screws would be far easier, cheaper and give more peace of mind. They really aren't noticeable to most people.

The problem with almost all hidden fasteners on ACM is that you can't screw into the back of the ACM to attach the fastener. And that leaves you depending on adhesive--but the hidden fastener is usually too small to have enough surface area of adhesive to hold the sign up. That's why screwing a larger piece of material to the wall (but smaller than your sign) is good. It allows a large surface area for VHB or adhesive, a surface which is smooth and provides good adhesion.

Evan Gillette

New Member

I see thickness details, but nothing for weight. They are quite nice....... if they work.

https://button-fix.com/files/Technical_Global/Technica/Button-fix_strength_testing-report.pdf

They have a couple others for other materials as well. I didn't look at them to see what type of fastening was used. Most of the application examples appear to be indoor architectural paneling installations.

The problem with almost all hidden fasteners on ACM is that you can't screw into the back of the ACM to attach the fastener. And that leaves you depending on adhesive--but the hidden fastener is usually too small to have enough surface area of adhesive to hold the sign up. That's why screwing a larger piece of material to the wall (but smaller than your sign) is good. It allows a large surface area for VHB or adhesive, a surface which is smooth and provides good adhesion.

I mostly agree and we've made simple rectangle signs the way you've just described but find that 6mm or thicker Alupanel has thick enough aluminum to get a good grip on short sheet metal screws used in conjunction with VHB and adhesive.

The key being that the bigger area you have to absorb the sheer force and gravity from the sign itself, the better it will hold.

Johnny Best

Active Member

If this 4x5 cut out piece is having vinyl put over it then I would attach the french cleat countersinking screws through face and sand and Bondo flat. The cleat would be secure enough to handle weight and no hardware will show.