adamfromayr

New Member

Hi

Im using Mach3

And i know that making sure a CNC is good, well one way is to make a perfect circle?

After i set up Mach3 Using "Set Steps per Unit"

And "Motor Tuning"

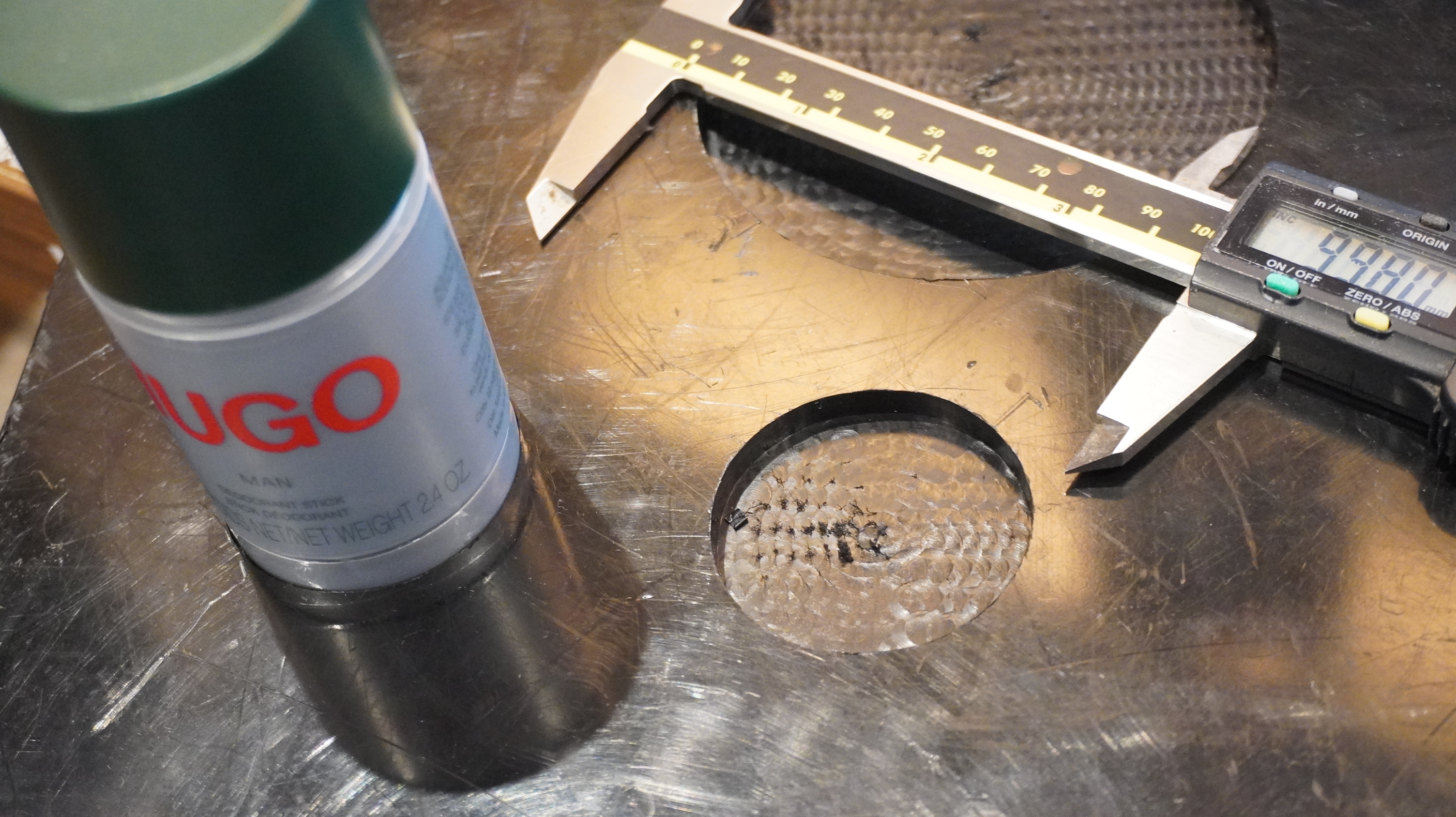

99.5 vs 99.8 mm

Ive made a few Test circle cuts and measured them afterwards using my Calipers!

Im just wondering to ask CNC Pros is the circle attached good enough?

It measures a difference of around 0.3mm in different areas!

So its like 99.7% good but is not 100%

Do you need it to be 100%?

I wonder if others do this test also?

Im using Mach3

And i know that making sure a CNC is good, well one way is to make a perfect circle?

After i set up Mach3 Using "Set Steps per Unit"

And "Motor Tuning"

99.5 vs 99.8 mm

Ive made a few Test circle cuts and measured them afterwards using my Calipers!

Im just wondering to ask CNC Pros is the circle attached good enough?

It measures a difference of around 0.3mm in different areas!

So its like 99.7% good but is not 100%

Do you need it to be 100%?

I wonder if others do this test also?