Valid question... So our graphics department is its own company. It is owned by a much larger Fortune 500 company. To make a long story short, poor previous management lead to the larger company going through a restructure and eliminate/replace most everyone in the department. I was brought in to manage & rebuild the graphics department. I have 20 years management, 10 years offset printing, a handful of years window tinting and paint protection installation, and 17 years of just solid color vinyl decal experience. I personally own a Mutoh 48" Valujet that I purchased about 13 years ago that I dabbled with banners for about 5 years before it broke on me and I never fixed because I quite frankly didn't have the volume to fix it, so I changed direction with my own business. I have a basic understanding of the wide format printing industry and am super excited to get back into it, I know I have A LOT to learn. My current team is solid, has a great attitude and everyone is on the same page and wants to learn & grow. We have 3 wrap installers that are really good and 1 in training. Our 2 graphic artists are really good designers with limited knowledge of the printing side of things. Our 2 production girls, who do all the printing/cutting/masking, both had zero experience before being hired 4 months ago, they have learned a lot and are very eager to learn more. I have 1 sales guy who is a rock star at selling graphics/wraps with 7yrs exp. Our 2 HP printers were installed 6 months ago and have been nothing but problems. Apparently, after several months of tech visits, they determined that we received 2 of their known bad manufactured printers. One of them was replaced already and the 2nd replacement is here and being installed on Tuesday. IF the HP tech did teach/tell us about the app and how to set up profiles initially, then that knowledge left when the old employees left. I will be making sure the tech that comes to install the 2nd replacement printer on Tuesday teach me and our 2 production girls how to use them. I'm learning as much as I can each and every day with lots of research inside and outside of work hours. It's kind of sad/embarrassing the amount of machines/material that we have at our disposal but lack the knowledge of how to use it all. We are all here eager to learn, we just need some direction.

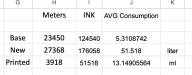

Our biggest problem right now is color matching & consistency. Customer provides us with their company branded color and we just can't seem to hit it (or spend 4-5 hours trying to). Even solid color panels have varying shades from the left side to the right side of the material when we line up 2 panels side by side. In theory, if we have 2 identical printers printing the same exact file, they should print exactly the same or damn well close enough to each other so that we can use both HP Latex 800 printers to print a vehicle wrap and have the colors line up. The amount of material and labor we are wasting on every job right now is embarrassing and needs to get corrected ASAP. If we can stick to ONYX and get things corrected and dialed in, then I'm all for it.