Susan Stewart

New Member

Good morning all.

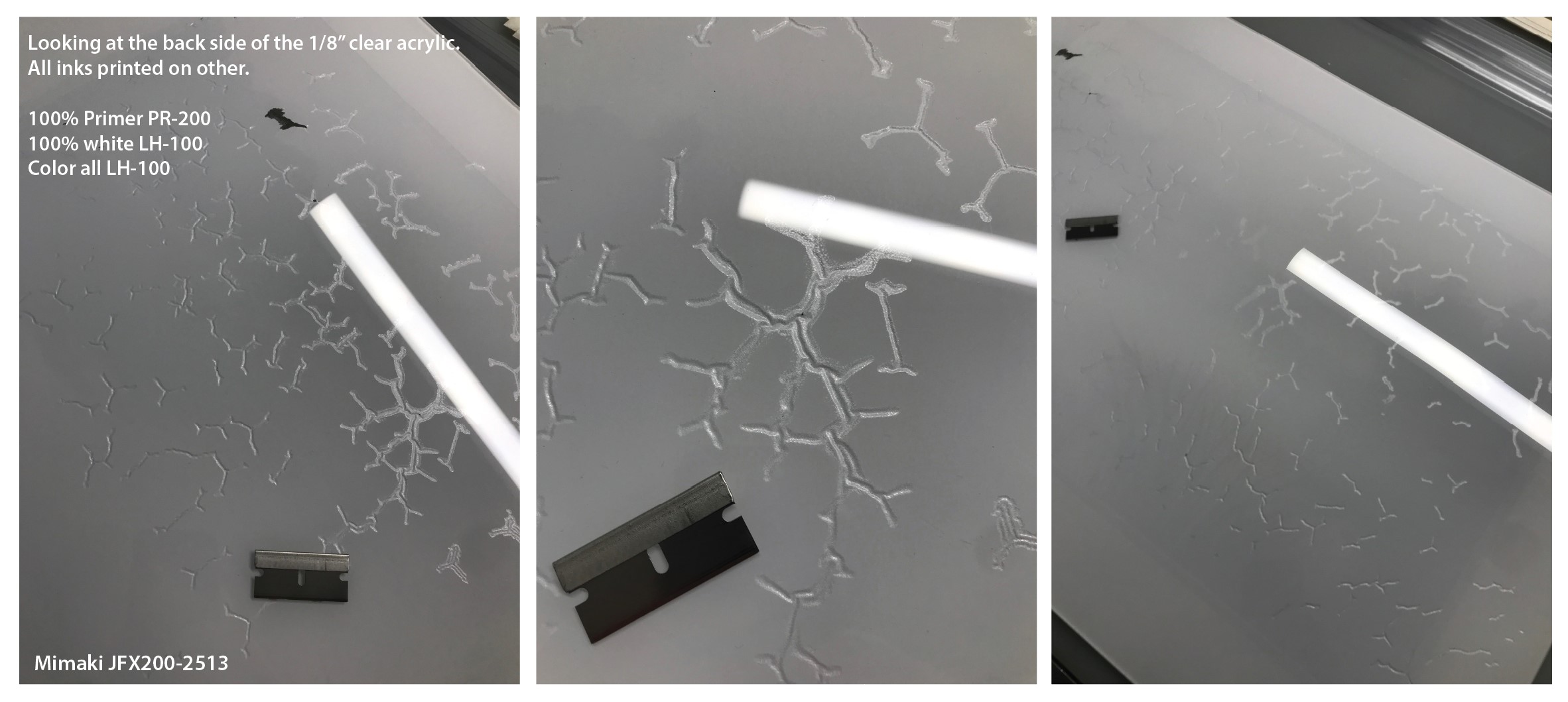

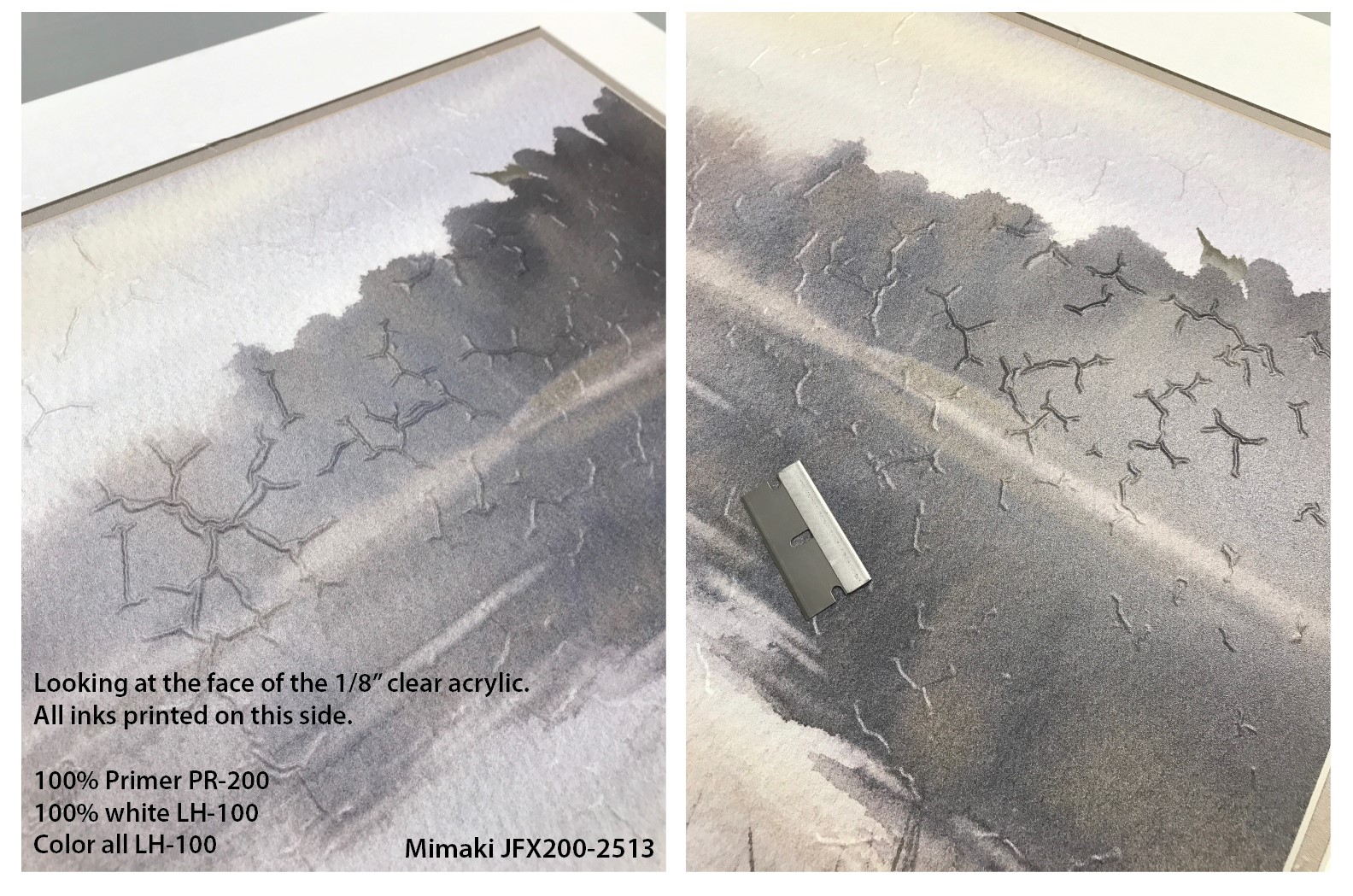

We have a product that we cut on our CNC router and then print it on our Mimaki JFX200-2513. The substrate is 1/8" clear acrylic. We have been producing this product since August 2020 with no issues. We have produced over 2,000 parts. We sell them to 6 different plants. We have 1 plant that started having issues with delamination a couple months ago. We do not believe this problem is being caused by anything that we are doing. We produce them the same way every time. We are cleaning them before printing them with a 50/50 mixture of distilled water and isopropyl alcohol. We believe it is something they are doing seeing as how the other 5 plants that we sell to are not having any issues. We are using LH-100 inks except our primer which is PR-200. I have attached pictures of one of the worst pieces to show you what they look like.

We tried putting different liquids on the printed acrylic to try to figure out what is causing this problem, but we were unable to recreate this. We tried water, isopropyl alcohol (90%), hand sanitizer, simple green, glass cleaner, and brake kleen.

We pulled off the ink on one of these raised spots, and the primer was still on the acrylic.

Does anyone know what would cause this?

We have a product that we cut on our CNC router and then print it on our Mimaki JFX200-2513. The substrate is 1/8" clear acrylic. We have been producing this product since August 2020 with no issues. We have produced over 2,000 parts. We sell them to 6 different plants. We have 1 plant that started having issues with delamination a couple months ago. We do not believe this problem is being caused by anything that we are doing. We produce them the same way every time. We are cleaning them before printing them with a 50/50 mixture of distilled water and isopropyl alcohol. We believe it is something they are doing seeing as how the other 5 plants that we sell to are not having any issues. We are using LH-100 inks except our primer which is PR-200. I have attached pictures of one of the worst pieces to show you what they look like.

We tried putting different liquids on the printed acrylic to try to figure out what is causing this problem, but we were unable to recreate this. We tried water, isopropyl alcohol (90%), hand sanitizer, simple green, glass cleaner, and brake kleen.

We pulled off the ink on one of these raised spots, and the primer was still on the acrylic.

Does anyone know what would cause this?