nolanola

https://manhattansignshop.nyc/

Hello.

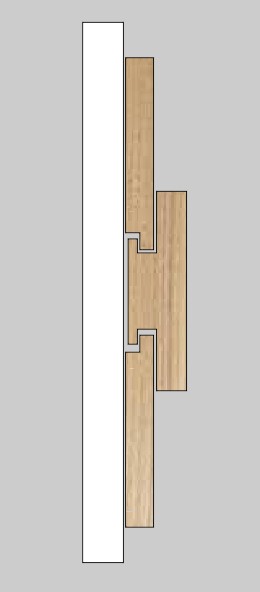

What would be the best way to produce something similar to the attached image?

We have a cnc machine and a laser to engrave the logos.

The client states that the panels should be able to slide in the tracks.

i'm thinking about a table saw.

Am I right?

What would be the best way to produce something similar to the attached image?

We have a cnc machine and a laser to engrave the logos.

The client states that the panels should be able to slide in the tracks.

i'm thinking about a table saw.

Am I right?