jbarry14

New Member

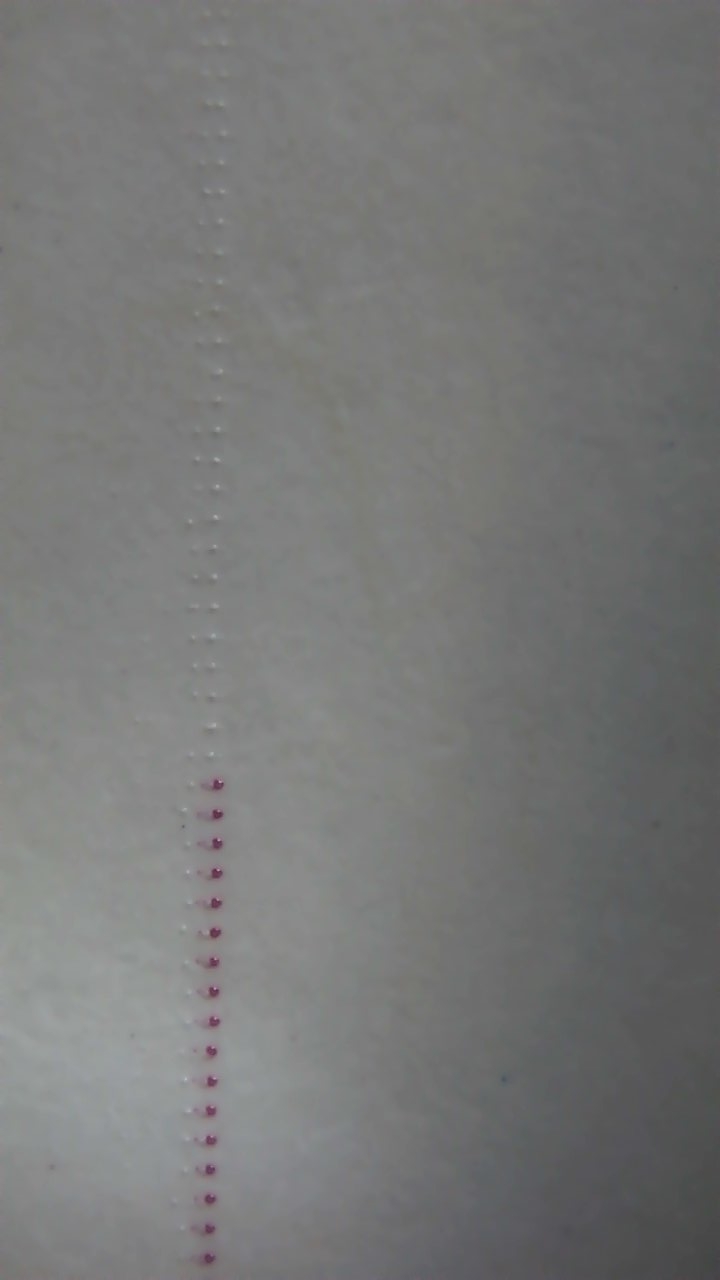

JFX200-2513. I am having problems with the white ink. It is creating almost like a mist, deflection, or shadows to our prints. I have replaced the white ink filters, put in new white ink. I changed the head gap to 1.5mm, I have done all the digital alignments. Have adjusted the head voltage. We had new heads put in about a year ago. I also get good nozzle checks. No matter what I have done, The white ink continues to print the same way. In one of the images I attached, you can see during the digital alignments, there are 2 lines for the white alignments.