Good day everyone,

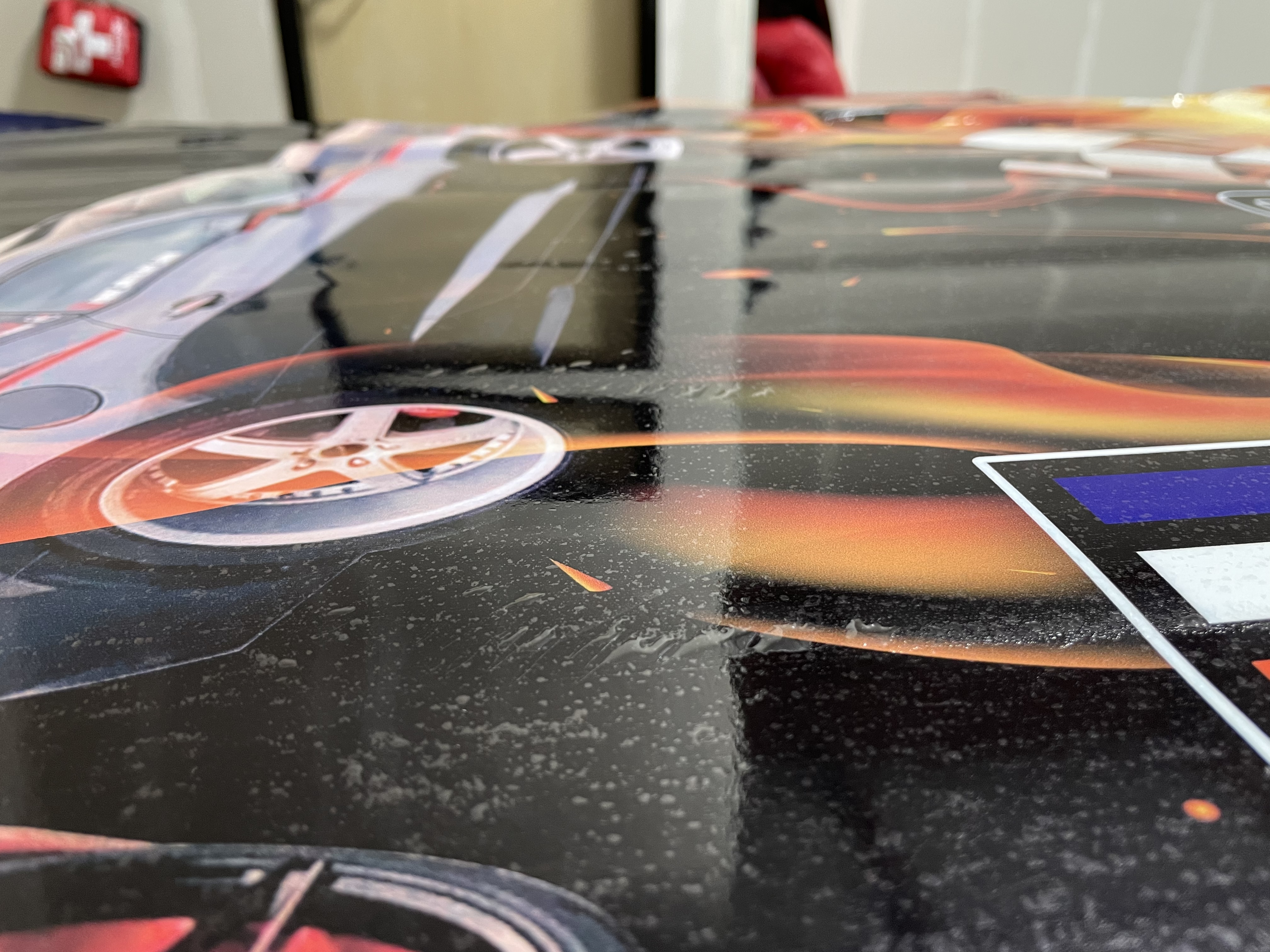

New to the group, and industry. But can anyone please please tell me why I would be getting small bubbles and wrinkles in the middle of my media every time I laminate. I have even pressure on the rollers and everything set up right to my knowledge. This issue just started happening and I’m curious if my laminator is just a POS or if I am at laminating. At this time any answer would help. Thank you.

New to the group, and industry. But can anyone please please tell me why I would be getting small bubbles and wrinkles in the middle of my media every time I laminate. I have even pressure on the rollers and everything set up right to my knowledge. This issue just started happening and I’m curious if my laminator is just a POS or if I am at laminating. At this time any answer would help. Thank you.