GAC05

Quit buggin' me

Not quite sign stuff but I did wrap them with 2080 matte black and did the logos on the outside along with all the police gear.

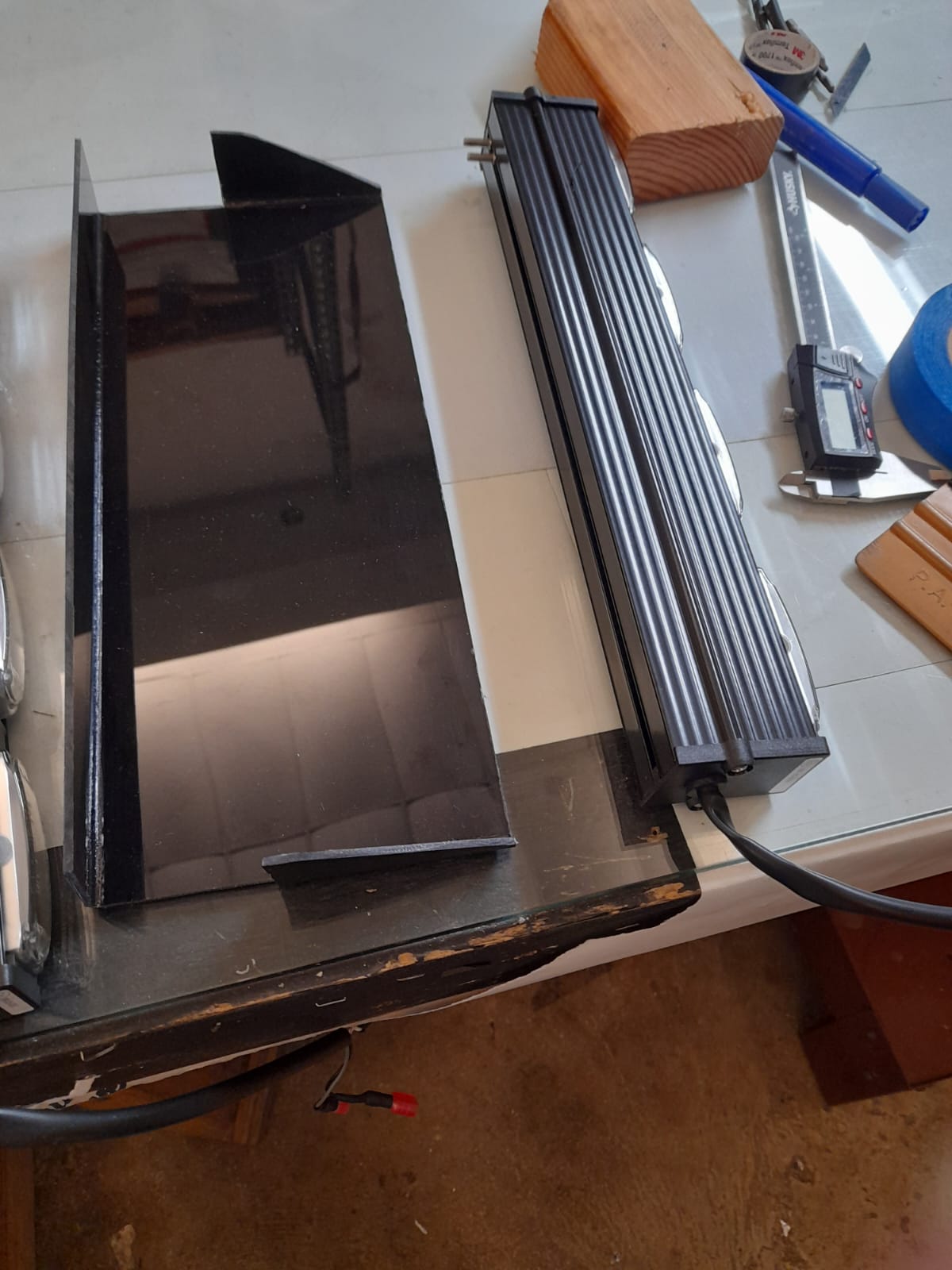

I made a small vice-mounted brake so I could cold roll these light guards (they keep the LEDs from flashing back off the windshield into the driver's eyes) into shape. Used thin polycarb and everything was tight and flush but after a few weeks with them parked out in the sun the folds started to relax and spring back away from the 90-degree bends. Looked it up, and I guess I am supposed to bake them after folding to set the Lexan.

"When polycarbonate is bent professionally, the sheet is folded into the desired shape when cold and then heated in an oven at a low temperature (maximum 70 degrees)."

That temp seems pretty low and these are wrapped in black, inside a black SUV near the windshield under a tropical sun. When these vehicles sit it gets a good deal warmer than 70 degrees inside.

Would it be worth a try to reset the bends, then hit them with a heater gun to hold the fold (same as post-heating cast vinyl), or give up - scrap these and redo them with some aluminum?

I made a small vice-mounted brake so I could cold roll these light guards (they keep the LEDs from flashing back off the windshield into the driver's eyes) into shape. Used thin polycarb and everything was tight and flush but after a few weeks with them parked out in the sun the folds started to relax and spring back away from the 90-degree bends. Looked it up, and I guess I am supposed to bake them after folding to set the Lexan.

"When polycarbonate is bent professionally, the sheet is folded into the desired shape when cold and then heated in an oven at a low temperature (maximum 70 degrees)."

That temp seems pretty low and these are wrapped in black, inside a black SUV near the windshield under a tropical sun. When these vehicles sit it gets a good deal warmer than 70 degrees inside.

Would it be worth a try to reset the bends, then hit them with a heater gun to hold the fold (same as post-heating cast vinyl), or give up - scrap these and redo them with some aluminum?