Kinkajou

New Member

Hi.

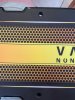

I'm having a light banding issue so I started a media compensation test. Current value is 0. I noticed that at the start of the print, on the far right, the lines do not touch. They start touching near the far left of the paper and then, at the end, overlap. How is that possible?

What should I do?

I'm running this test o a Mimaki CJV150-160 and Avery Dennison MPI 2006 (high tack). Heaters 40 40 50.

EDIT: just some additional info. I replaced my print head some months ago with a compatible one. Maybe it was not installed totally straight?

I'm having a light banding issue so I started a media compensation test. Current value is 0. I noticed that at the start of the print, on the far right, the lines do not touch. They start touching near the far left of the paper and then, at the end, overlap. How is that possible?

What should I do?

I'm running this test o a Mimaki CJV150-160 and Avery Dennison MPI 2006 (high tack). Heaters 40 40 50.

EDIT: just some additional info. I replaced my print head some months ago with a compatible one. Maybe it was not installed totally straight?