While the test draw is actually very very good it is also possible that the head is simply getting worn out. But there is some confusion there. In the first post you said the printhead and capping station were both replaced about a month prior but then you say in post #6 that the print head and dampers are original to the machine. Considering Mimaki came out with the replacement for the JV33/CJV30 machines (The JV150/CJV50 / 300) in 2014 I'd venture to guess that the printer is at minimum at least 5 years old, potentially far older as the JV33/CJV30 machines came out in 2008. So in that light, if it is on its original printhead and still has just a single nozzle missing, that is pretty darn good!

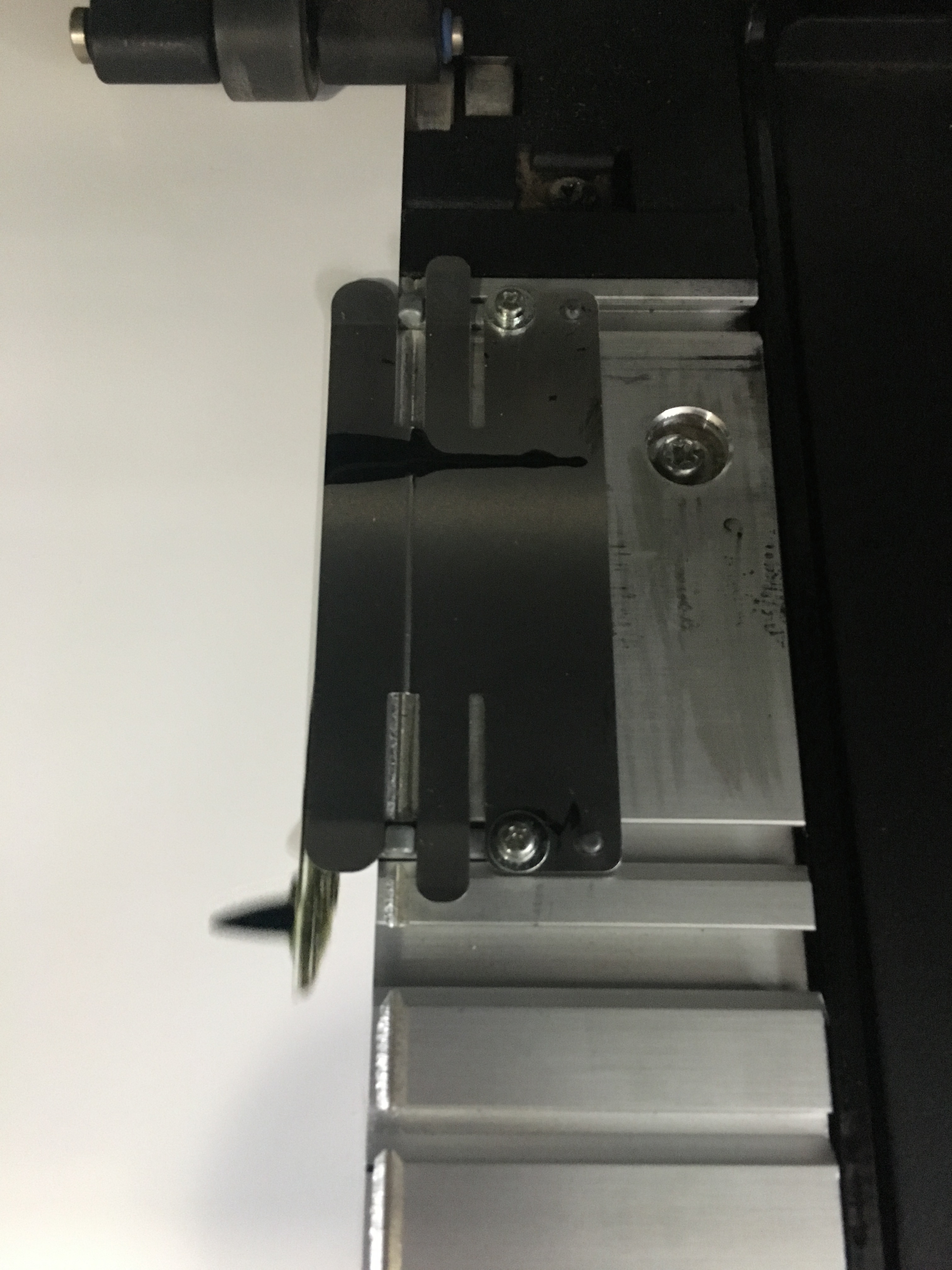

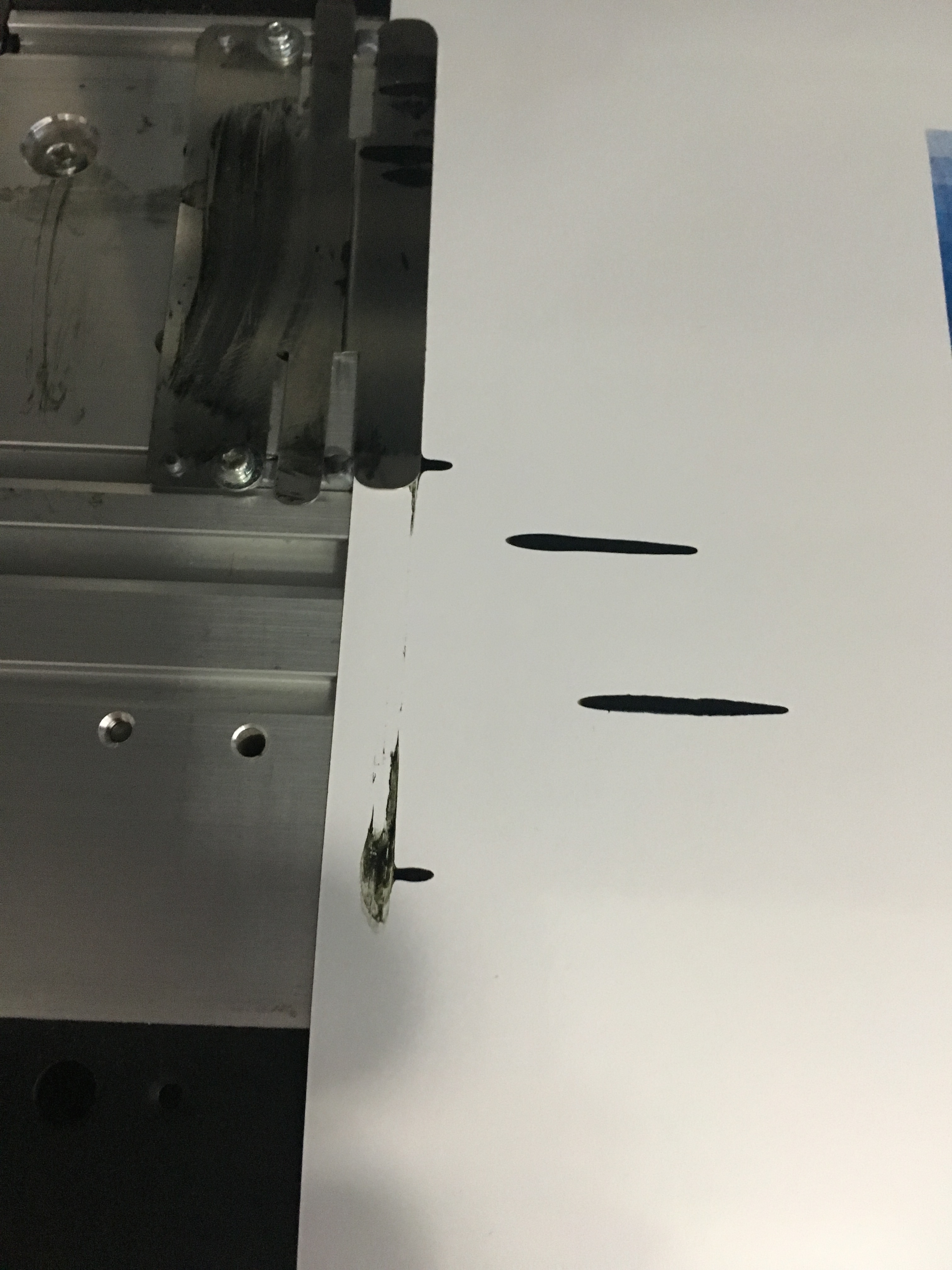

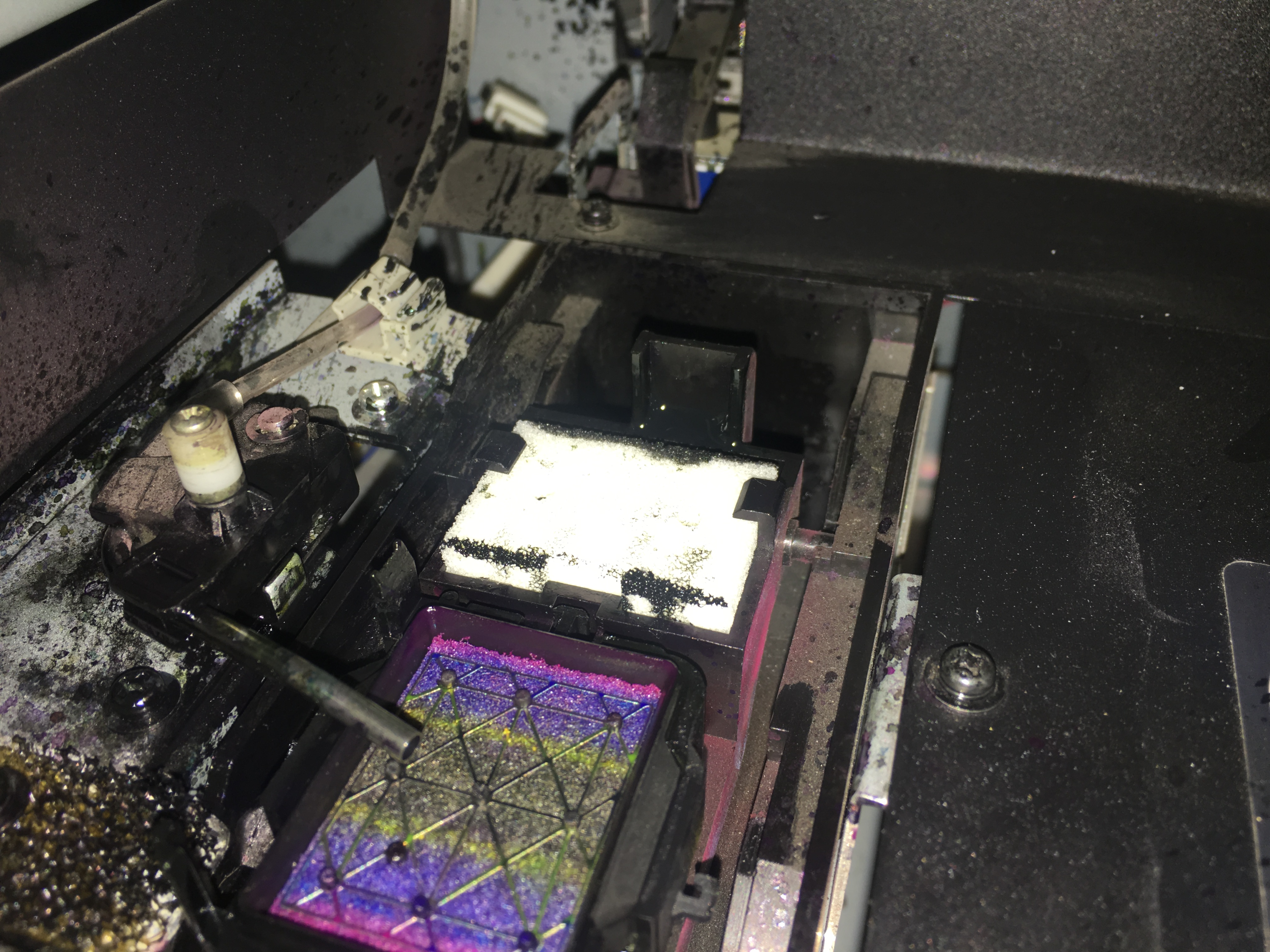

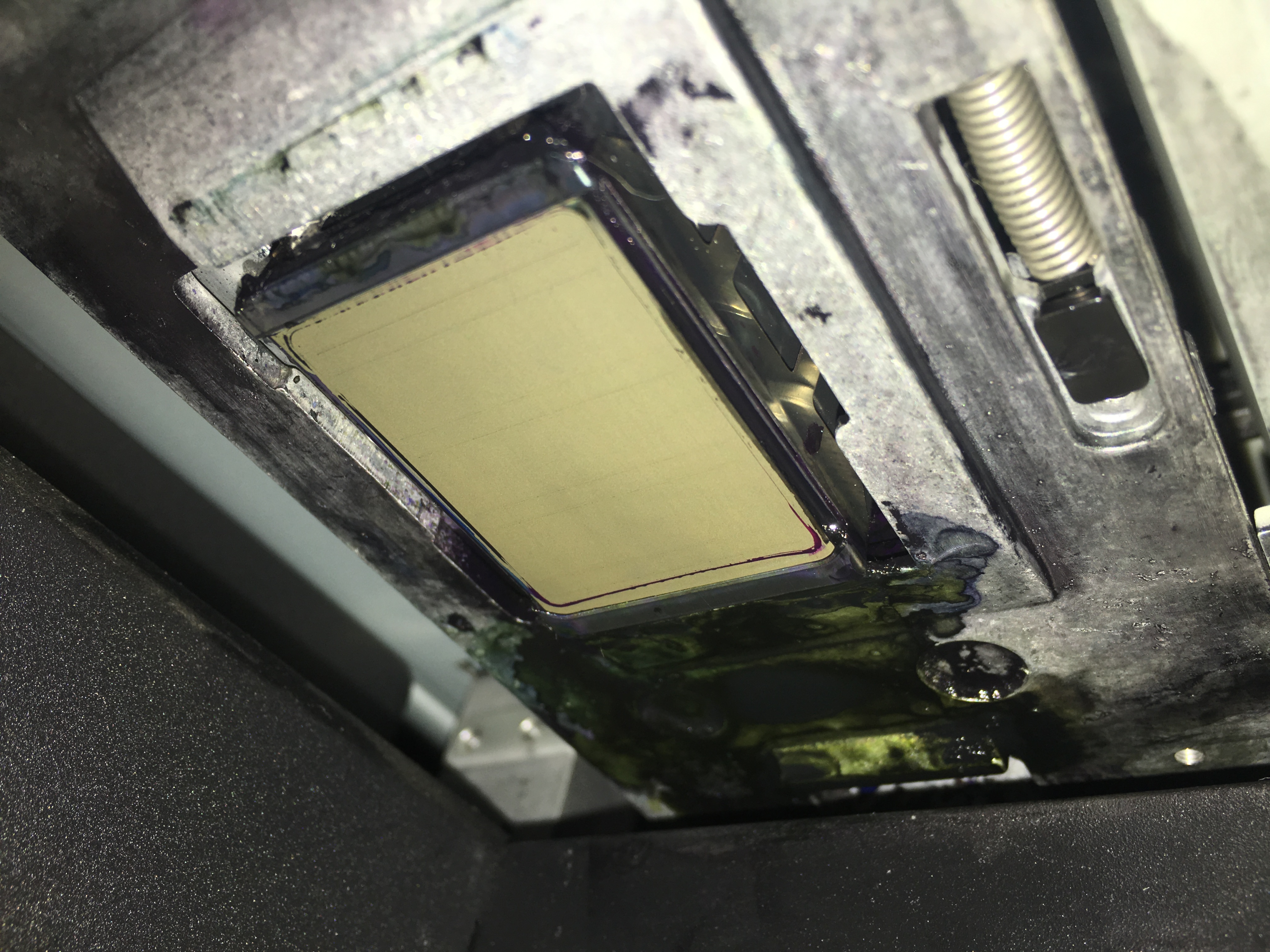

On your issue though. It still need a lot of cleaning. In that last photo you can see a big blob of dried ink connecting the print head to the carriage. It is not enough to just clear around the head. You need to occasionally clean the bottom of the entire head carriage. A tiny piece of fuzz stuck on the bottom of the carriage even an inch away from the head can disturb the air as it is quickly moving back and forth and cause print issues. With the age of the machine, depending on its maintenance history it might be time to replace all dampers, joint valves, capping top, and possibly the pump. All of these are cheaper than a printhead but its possible as I said, that the printhead itself could just be nearing the end of its life. Hard to say really though as that also depends on if the usage in its life has been very light compared to say printing non-stop 8+ hours a day 5 days a week or more.

That being said there are a number of things that can cause dripping at the printhead or what might appear to be such. Some of the more common things could be....

fuzz or something stuck on the bottom of the print carriage or head (just catches and collects ink as it runs)

failing printhead (usually will see misting on prints, but not necessarily a test draw)

aftermarket bulk ink systems that use open tanks (can cause all sorts of pressure issues in the ink system)

some aftermarket inks themselves can cause all sorts of issues

cartridge slot solenoid valve sticking open or failing (can cause excess pressures on the dampers when the machine is not expecting flow from the cartridges)

weak or failing dampers (there is a valve in them)

wiper worn out, not working, or just totally missing (if it cannot wipe excess ink off, well it just stays on the bottom of the head then)

clogged or failing pump (if it cannot get the ink out that it expects to then it just stays on the bottom of the head and in the cap top)

I'd also carefully inspect the wiper station. Over a long period of time ink can get built up enough that the entire station needs to be removed and thoroughly cleaned as there will be so much ink buildup that the wiper can pretty much no longer move freely.

One important thing I've learned the hard way more than once over the years is not to skimp on certain parts. I've never had an aftermarket pump last more than a year while and OEM one will last 5+ years. Dampers and capping tops are hit and miss. Sometimes generic ones works fine while other times I've had them start leaking almost immediately. I've brand new generic cap tops with air leaks brand new, and I've seen complete generic capping stations that are poorly formed and weak that will not line up go. I eventually learned my lesson and started buying only original genuine OEM Mimaki parts when needed. For some reason they just last far longer.... Some bits like wipers, foam pads are not as critical though.

Its a lot to consider but these machines are a lot more complex that one might think. That is why a couple of techs have chimes in that your best bet might be to get a professional tech in to fix it up. One thing I'd also suggest in that scenario is to get some assurance that the tech is experienced with Mimaki printers and that the company sending the tech uses only genuine OEM Mimaki parts. Without knowing what to look for though most would not know any difference between generic part packaging and labelling versus generic though. My point on this is just that if you are going to spend the big $$$$ for a professional tech, they better know what they are doing, get it done right, and stand by their work. While the JV33/CJV30 machines are now a bit older they are still absolute workhorses and are leaps and bounds better than the truly antique JV3 machines some are still trying to keep going. As long as it is taken care of and fixed right a JV33 in good condition should still be a perfectly capable and solid machine. Good luck!