tatotiburon

New Member

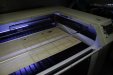

Hi, i'm running a bussiness in my town with promotionals products, id tags, signs, etc....right now i have a mimaki 3042 but i'm looking for a great laser cut machine for acrylic cut, engraving silicone bands, marking metal items and more aplications...

i don't really know much about this machines, i know the epilog fusion, saw it in a friend's of mine store and i loved it, but you're the experts, is this a good machine or can i find a better option for my needs for a better deal

Thanks for your help

i don't really know much about this machines, i know the epilog fusion, saw it in a friend's of mine store and i loved it, but you're the experts, is this a good machine or can i find a better option for my needs for a better deal

Thanks for your help