So, we have three of us working on this beast - the first is our production worker, second the owner, and me pulling up the rear with the least amount of experience running it. Tunneling was the first issue right out the gate. The print would dish out from the center and wrinkle on the sides. So the boys threw out the clock face technique - I'm guessing they weren't feeling the touchdown right? So now they just start at touchdown and don't do the one hour increase. Seemed to have helped and the print runs through smoother.

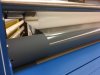

The issue now is vertical creasing in the laminate as it rests on the roller bar. As the bar heats up (we have it set low at 95 and it maxes out at 115 degrees) the laminate ripples, smooths, and then ripples again as we run it. This usually hasn't caused any visible problems on the prints and the boys are chalking it up to "you can get away with more" than our old school cold laminator that needs to be webbed FLAWLESSLY. We're also running into craft paper wrinkles that we can't smooth out without rewebbing the laminate - they tried rewebbing 4 times in a row one day. Our print this morning got trashed - craft paper was wrinkling underneath, got bubbles and silvering right at the start, the print pinched on itself at the end and the laminate ended up with big creases. It was a royal mess. Roll to roll big prints seem to be working out ok, but about 60% of our short one-off prints gets trashed. Unfortunately since I've touched it the least, I mostly see the start and end, not much of the tweaking in between or what all has been messed with up until this point.

We've only run glossy calendered vinyl and laminate through this machine so far. (Tried matte once, but that was a huge failure too, so back to working out the kinks with just the gloss)