MGB_LE

New Member

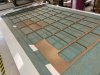

This is the eucaboard material from Home Depot, in 48x96" sheets: Eucaboard Info. We are simply cutting out 52 6" x 11" boards. Most do OK, but the last row sees some boards start to lose suction and move around. Then they aren't cut square. We have used Colex bits T00498 and T00535, and the boards are fuzzy and require sanding to get clean edges. Normally we do 52 at a time, but the client ordered 2,000 and we weren't really ready to scale up.

We're running CCC8 on our 60x120" Colex. I've attached photos of the during and after, and the finished product. We used a belt sander to clean up the edges. What can we do to keep the boards still and square? Tabs might significantly increase the final finishing time. Please educate us.

We're running CCC8 on our 60x120" Colex. I've attached photos of the during and after, and the finished product. We used a belt sander to clean up the edges. What can we do to keep the boards still and square? Tabs might significantly increase the final finishing time. Please educate us.