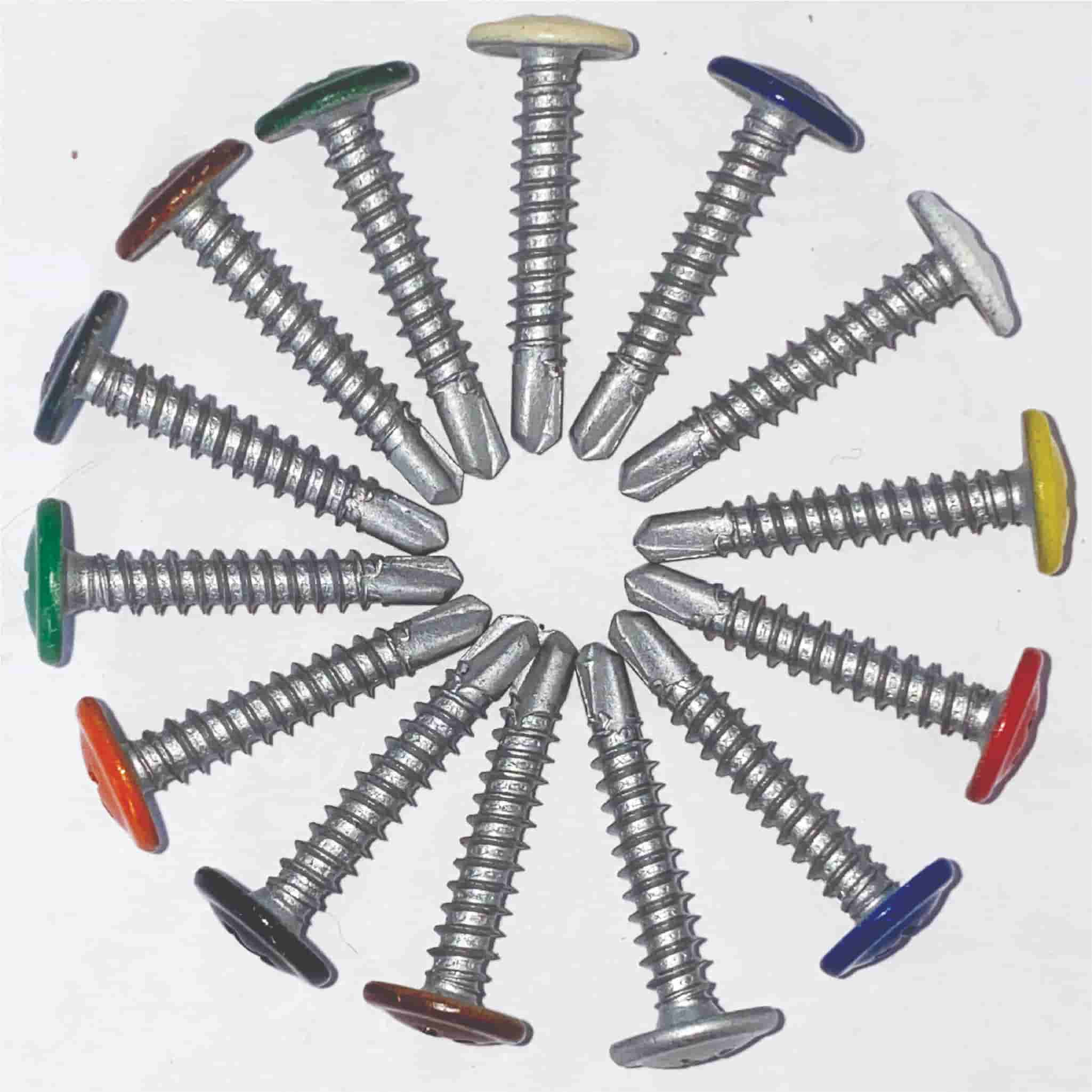

Hey everyone I found some cheap Coloured Screws Online. We used to use Signgears however these are the exact same but cheaper and also work with masonary plugs (not sure if Signgears did). They offer different size packs 25s 50s 100s, they also offer a Starter Pack which I purchased first which was 20 of each colour and a Magnetic Screw Sleeve which helps hold the screw when they go in. They are Self Drilling, Self Tapping, Rust Proof and I believe they have 13 different colours which are RAL coded.

If you're interested, I found these on www.colouredscrews.co.uk. They've got a decent selection, and the prices seem reasonable to me. Of course, you can always hunt around for other options too, but I thought I'd give everyone a heads up on these.

If you're interested, I found these on www.colouredscrews.co.uk. They've got a decent selection, and the prices seem reasonable to me. Of course, you can always hunt around for other options too, but I thought I'd give everyone a heads up on these.