DisplayWorks S&G

New Member

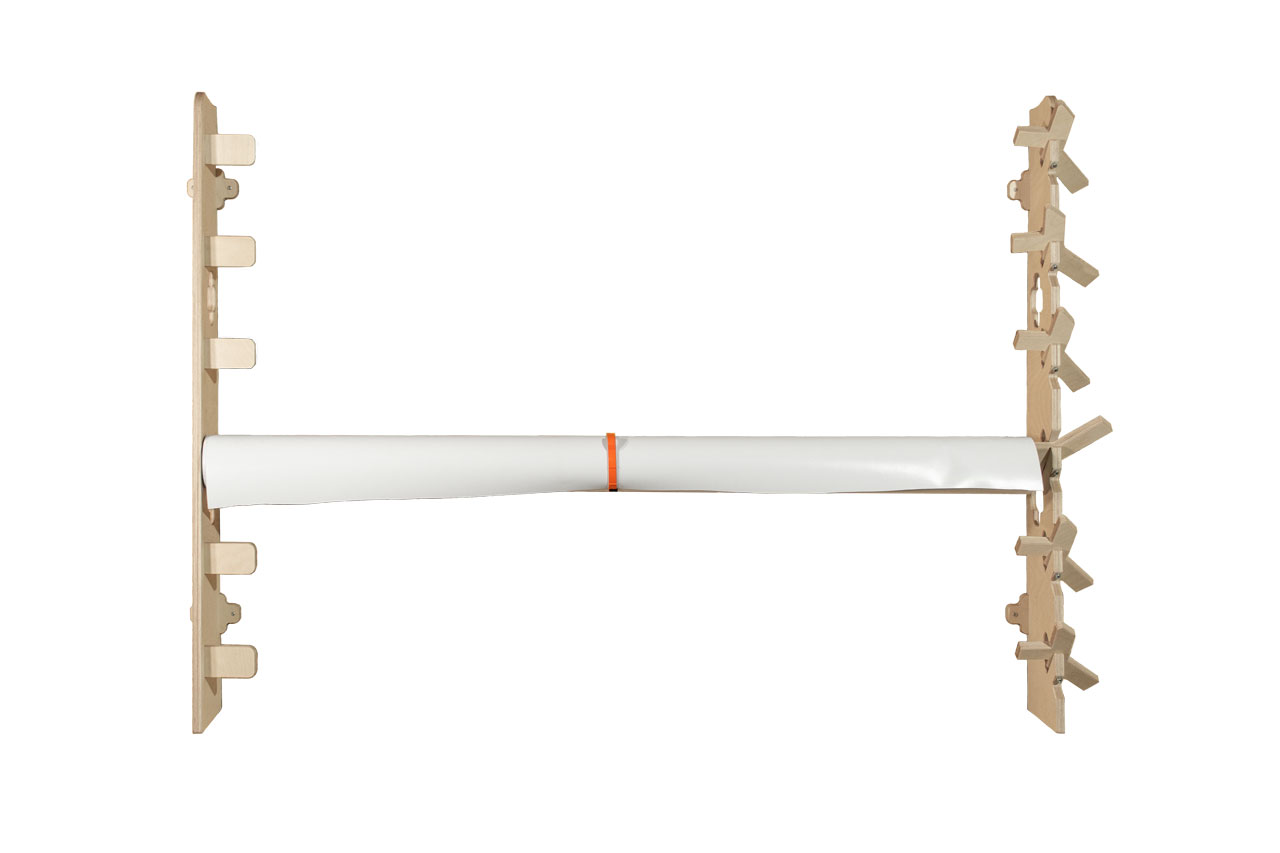

Hey everyone, just wondering if anyone had any really cool ideas for storage of finished graphics. Example would be masked graphics or produced vehicle graphics. Something that uses a small footprint.

Would LOVE to see some photos of your storage techniques!

My idea was to make wide shelves along a wall with 4 inch gaps. Hoping to keep graphics flat for the most part.

Would LOVE to see some photos of your storage techniques!

My idea was to make wide shelves along a wall with 4 inch gaps. Hoping to keep graphics flat for the most part.