Looked a little over engineered. I would simplify it. There is a book:

http://www.amazon.com/Sign-Structures-Foundations-Designers-Estimators/dp/0911380655/ref=pd_sim_b_3

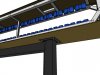

Below is what I would send to engineering (please note not to scale or proportion)... basically angles, support plates inside, let the post slide in and bolt it down

Rick has the right idea. In areas with high windloads, it's better to extend the support(s) completely to the top of the cabinet. Bolt and weld the supports to steel framing. This eliminates the suport-to-

sign connection becoming the weak point(s). Your faces will be the first to go, followed by the filler in extreme circumstances.

Running your supports to the top makes lighting a bit more of a challenge, but it's more important that the cabinet withstand the local conditions.

Your original idea was using what are referred to as matchplates. They would probably be just fine and may meet local engineering requirements, but in an area like yours it's better to over-engineer and go with the supports all the way to the top as Rick mentioned.

Forgot to mention: Check out ABC

Sign Products. They can provide exactly what you need. (

link)