0x0f

New Member

Hi,

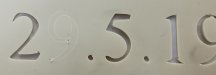

We've got an older SummaCut plotter and a D60R, mostly for cutting sandblast resist. The older plotter, I believe, is more geared toward this purpose while D60R - as I understand - is not the best. But it's been a serviceable setup for a while now. However recently the D60R has had problems such as the picture I've included:

It doesn't completely cut the outer stroke of the numeral 9 I haven't weeded out. Interestingly the other 9 to the right was cut a little better; the problematic nine is more toward the middle of the 50 cm wide resist spool. I'm not an expert with these so I'm wondering if this is a worn knife or what might be the issue. While the plotter has had its problems it did not do this before.

Thanks

We've got an older SummaCut plotter and a D60R, mostly for cutting sandblast resist. The older plotter, I believe, is more geared toward this purpose while D60R - as I understand - is not the best. But it's been a serviceable setup for a while now. However recently the D60R has had problems such as the picture I've included:

It doesn't completely cut the outer stroke of the numeral 9 I haven't weeded out. Interestingly the other 9 to the right was cut a little better; the problematic nine is more toward the middle of the 50 cm wide resist spool. I'm not an expert with these so I'm wondering if this is a worn knife or what might be the issue. While the plotter has had its problems it did not do this before.

Thanks