-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

Cjv30 repair

If you fry one board, you need to check the other boards. The damage could lead back to the main board. You need to check all the fuses etc. Probably best that you replace the board entirely. -

-

-

Rasterlink 6 pro & JV33 cleaning question

This only determins a set desired length. I want a cleaning cycle to start at the end or begining of a print. As I do many large format prints, setting it as per above isn't benifical as some prints are 3m, some 4 etc.... -

Red/white blue/white laser cutters

So these come with a camera to read rego marks?- Forty One

- Post #4

- Forum: CNC Routing & Laser Cutting

-

Red/white blue/white laser cutters

I'm looking at a 100w CO2 laser and thinking if I should get one of those Chinese ones on eBay. Has anyone picked up one of these units? Your opinion? $6k v $30k is a considerable thought to have about these- Forty One

- Thread

- Replies: 5

- Forum: CNC Routing & Laser Cutting

-

Rasterlink 6 pro & JV33 cleaning question

I'm trying to find if there is a way to schedule a cleaning cycle either before or after a print for the JV33. In the printer settings, the only 'scheduled' cleaning cycle is either Auto or Print and then the length can be dialed in. E.G. cleaning cycle after 2000mm etc, unless I'm missing... -

ONYX THRIVE 19 RIP EPSON EDITION + dongle

is the onyx still on the table?- Forty One

- Post #12

- Forum: RIP Software & Color Management

-

Question onix ver.19

your biggest isue will be the prninst file. And since it's long forgotten, you will need to source it on the deep web. In short, don't use the cracked version. there's no library available.- Forty One

- Post #4

- Forum: RIP Software & Color Management

-

Easy way to install floor graphics?

Thanks, that lino roller thingy looks like it would be on point- Forty One

- Post #8

- Forum: Installation Equipment & Techniques

-

Easy way to install floor graphics?

1. I'm using Texwalk. 2. longevity approx 3 months. What I'm installing is mainly linemarking. approx 300mm (1 foot) wide x 1200mm -2400mm (4 - 8 foot) length strips. about 380 units total- Forty One

- Post #5

- Forum: Installation Equipment & Techniques

-

Easy way to install floor graphics?

Hey all, I have a job coming up where we will be installing quite a bit of floor graphics in a shopping centre. Does anyone have any tricks or ideas on application tools that will aid us in laying down the vinyl and won't destroy our backs?- Forty One

- Thread

- Replies: 7

- Forum: Installation Equipment & Techniques

-

Vinyl Wrapping a concave wall questions.

We use a high tack vinyl when we do our wall prints. And because of that, we spray the walls down with a litte soapy water. Just enough to make sure the prin doesn't bite immediately and we can reposition as needed. This worked a treat when I had to apply it to a curved wall.- Forty One

- Post #2

- Forum: Tips & Tricks

-

Mimaki JV33-160 problems after error 202

202 is a head error. The change of the parameter #76 is only for firmware versions v4.4 and above. Why did you get the head error? Why did you change the parameter? I would go and change the parameter back to normal and do a full power down reboot. 202 generally referrs to a head ID or... -

UJF 7151 plus thread.

Never mind. I found it under the resource library in Mimaki's website. But it's called Table tap position DXF data If anyone else needs any resources for this machine.... https://www.mimakiaus.com.au/product/inkjet/i-flat/ujf-7151plusII/download-manual.html -

UJF 7151 plus thread.

I can't remember where to get the template drawing to create a jig for this machine. Can anyone lead me where to get it from? Google isn't coming up with anything -

advice needed for a Manual Treadle Guillotine

Can anyone give advice on a 1300mm wide guillotine? I'm getting mixed info from reps regarding what can and what can not be cut. Mainly they say that they are only made for 1 - 1.5mm stock. Composite panels, although are soft, the guillotine cant accomodate 3mm stock. Has anyone got one in...- Forty One

- Thread

- Replies: 1

- Forum: Miscellaneous Hardware

-

Question clear coat I KNOW FOR A FACT IT IS AQUEOUS

what's the base material you are spraying onto?- Forty One

- Post #2

- Forum: General Signmaking Topics

-

Mimaki 3D printed replacement parts

With the UJF 7151, it's not recommended to attach an extractor to the back as the airflow could effect the print. I installed a vent above the printer and ran the extraction that way. Has done away with the majority of the fumes, but could be better. As I go through and fix up the entire... -

Mimaki 3D printed replacement parts

Not on the JV33. these fans blow outwards. There would be no benifit in blowing onto unprinted media. The place where I got these printers from had the fume extraction system set up as such. -

Mimaki 3D printed replacement parts

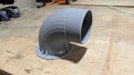

And said 'T' piece junction https://www.printables.com/model/1011877-mimaki-fume-extrraction-fitting-t-junction