-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

Looking for printable, no coating paper

We made so paper table cloths for a kids day. We ordered a 60# white kraft paper from Uline and printed outlines on a Seiko M64 a copule days before the event. There were no complaints. I guess it worked.- danno

- Post #5

- Forum: General Signmaking Topics

-

-

Banding on Epson s80600

It looks to me like there might be a temperature change as the machine warms up. Look to see if there could be slight buckling of the media as it moves across the platten. If there is, try dropping the pre and platten temps a couple degrees.- danno

- Post #6

- Forum: Digital Printing

-

Marks are too far apart in X direction

We use Summa GoSign here. There is a plugin for Adobe Illustrator. It has automatically set everything correct so far. We do add a 1/2" all the way around after the registration marks are created. There might be a plug in on Summa's site for the GoProduce. -

Summa gosign doesn't recognize the cutter

We had to reconfigure GoSign to use a USB instead of the internet connection. Use the devices tab at the top. It searches automatically when opened at our shop. -

Looking for this.........................................

https://metalcraftindustries.net/... I have dealt with them in the past. They also make custom frames. I was pleased with their work.- danno

- Post #5

- Forum: Product and Supplier Referrals

-

The sound is making me crazy!!!

I have operated 2 different s80's. The first one Epson came and replaced the fan. It just changed the pitch. They also couldn't figure out how to resolve the issue. The one I am currently operating is in a smaller work area. The fan seems louder. Epson said it is normal. One tech couldn't... -

Custom Printed vinyl flooring

Is there anyone here in Signs101 land that can print 10' x 20' seamless vinyl flooring?- danno

- Thread

- Replies: 0

- Forum: Digital Printing

-

S80600 blotchy ink spots

I usually see that in the first wind or 2 of the media. I write it off as packaging. Does it do the same thing on another roll of media? -

Summa Length Issues

I used to cut bout 20' (240") back in the day with the first t160. We set everything manually back then. We were within a knife blade when we forgot to add a bleed.- danno

- Post #12

- Forum: General Chit-Chat

-

Pole clamp sleeves

I have used end pieces of 18oz banner.- danno

- Post #4

- Forum: General Signmaking Topics

-

Washed out colors with illuminated lightboxes

When I was printing UV we would print the image twice, one on top of the other. With our roll printers, we would print 2 images. One would be to an optically clear. We would then overlay on our light table to achieve correct registration.- danno

- Post #4

- Forum: Digital Printing

-

HP FB750 Need Help Printing on uneven surfaces

The inks for the FB were overfilled from HP. That was done to make sure the printer wouldn't empty the bladder and draw air into the lines. When I ran those units, I would start checking ink levels at 10% remaining. I could usually print until 0% remaining. We also shook our ink boxes once a...- danno

- Post #6

- Forum: Hewlett Packard

-

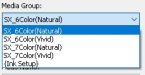

Need Help onyx12 is there a way to use 4 colors only while ripping ?

There is a way to use only CMYK in Onyx. It would require a custom profile build. Just curious on why you would only want the 4 colours?- danno

- Post #6

- Forum: RIP Software & Color Management

-

high temp vinyl, is there such a thing?

We were doing engine compartment decals a few years back. We ended up using 3M 480 with 3M 8580 laminate. The customer was sticking the decals to the valve covers of his race engines. -

Early browning on laminated IJ-180c sign in southern Arizona

8518, 8519 or 8520 would have been better choices. I have used 8548g and on high sun exposure did a double layer of 8548g for best results. -

new hardware

I have used Signburst computers for my builds. Casey knows what we need. He's very familiar with the industry and his support is AWESOME!!- danno

- Post #3

- Forum: Computer Hardware

-

How to Sell Gerber Edge Foils?

I'm interested in what you have also. Would you happen to have an Envison? -

Am I able to print on 3M 1080-G364 with my Mutoh 1624 ValueJet (EcoSolvent) Printer?

I printed on some 1080 films when they first came out. After laminating, I experienced some issues with ink/laminate adhesion to the surface. 3M told me the film wasn't ment to be printed on. When the laminate started peeling, it took the ink with it. I was printing with a Seiko M-64 and a...- danno

- Post #8

- Forum: Digital Printing

-

Avery Chrome Red

Good Morning, I am currently searching for 10 yards of Avery Chrome Red wrapping film. Avery is currently estimating 60 days on delivery. Any help would be appreciated. -

GFP Laminators?

We have an 865dh and it works really well. I've ran GBC, Seal, Kala and it seams to keep up with them really well. The thickest laminate we have run is a textured 5mil. It handled it really well. We don't use the heat and haven't had any problem with silvering.- danno

- Post #6

- Forum: Digital Printing