Centro Graphics

New Member

Hi All

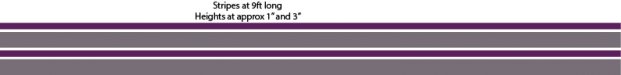

We have around 100ft of 2 color stripes to produce. Any suggestions welcome on keeping everything perfect straight on the plotter. Also getting the colors lined up as per image shown. Stripes are cut vinyl and not printed. We will be cutting at approx 9ft legths and joing together with slight overlap.

Appreciate any tips on this

Thanks

We have around 100ft of 2 color stripes to produce. Any suggestions welcome on keeping everything perfect straight on the plotter. Also getting the colors lined up as per image shown. Stripes are cut vinyl and not printed. We will be cutting at approx 9ft legths and joing together with slight overlap.

Appreciate any tips on this

Thanks