V-Pixel

Flatbed-Applicator Maker

Hey everyone,

after working in the signmaking world for quite a few years, I finally decided to tackle something that’s been bugging me for a long time — building my own flatbed laminator.

Why?

Because every time I looked at the commercial options out there, I couldn’t shake the thought:

“That’s a lot of money for what’s basically a frame, a roller and some pneumatics.”

My background is actually in mechatronics and industrial R&D, but I’ve always had a soft spot for hands-on signmaking and vinyl work. In my small workshop, space and budget are limited — so the idea was simple:

Build a professional-grade flatbed laminator that’s compact, modular, and affordable.

The project — which I call SignSystem 1320 — took about a year of spare-time development:

lots of CAD modeling, test builds, and adjustments.

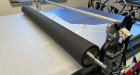

It’s based on standard aluminum profiles, precision linear rails, and a custom-made silicone roller.

I also integrated pneumatic lift controls, LED backlight, and optional features like a roll holder and mesh catch tray.

Here’s what I focused on:

I’ll share photos, renders, and some behind-the-scenes progress in the next posts.

This build might be interesting to anyone who ever thought about building their own equipment or optimizing their workflow without spending 6 - 10K+.

Happy to hear your thoughts, feedback or maybe your own DIY equipment stories!

Cheers from Germany

Manuel

after working in the signmaking world for quite a few years, I finally decided to tackle something that’s been bugging me for a long time — building my own flatbed laminator.

Why?

Because every time I looked at the commercial options out there, I couldn’t shake the thought:

“That’s a lot of money for what’s basically a frame, a roller and some pneumatics.”

My background is actually in mechatronics and industrial R&D, but I’ve always had a soft spot for hands-on signmaking and vinyl work. In my small workshop, space and budget are limited — so the idea was simple:

Build a professional-grade flatbed laminator that’s compact, modular, and affordable.

The project — which I call SignSystem 1320 — took about a year of spare-time development:

lots of CAD modeling, test builds, and adjustments.

It’s based on standard aluminum profiles, precision linear rails, and a custom-made silicone roller.

I also integrated pneumatic lift controls, LED backlight, and optional features like a roll holder and mesh catch tray.

Here’s what I focused on:

- Solid construction, not a wobbly frame

- Smooth and synchronized roller movement

- Easy-to-service pneumatic system

- Modular add-ons like lighting and storage

- A clean, professional look that fits any shop

I’ll share photos, renders, and some behind-the-scenes progress in the next posts.

This build might be interesting to anyone who ever thought about building their own equipment or optimizing their workflow without spending 6 - 10K+.

Happy to hear your thoughts, feedback or maybe your own DIY equipment stories!

Cheers from Germany

Manuel

Last edited: