Turbophein

New Member

Well i've been learning a lot and i feel i have most the basic stuff figured out... i finally printed, laminated and cut out a set of graphics! but i am still having problems with my colors, they are just terrible. this last week i have been researching with trial and error trying to get it right and i can't.

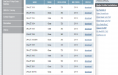

i found the roland color library in corel draw, so i decided to print it out. i exported it the same way as always and it came out terrible. the colors have small dots through out it, its never a true solid color unless its 100% of that one color and 0% of the rest.

so i did more research, and i found versaworks has its own color library, so i was hoping i could print that and have solid nice colors to look at but i was wrong, it might even be worse! if the color is mixed just a little, it looks like "snow" on a old t.v. its just terrible. look at the pics, and yes it looks just like that! that is right from the versaworks color library.

I downloaded, installed and printed with the 3165gra profiles. set my vinyl length, not sure what else there is to change when i'm printing right from versaworks.

as of now all i use is gloss oracal 3165ra vinyl. should i try other profiles? generic 1 was worse.

i would love for this to be a simple answer but i think it won't. i'm dying to get this going and customers are bugging me to get there jobs done! any help would be appreciated!!

thanks

Matt

Offsite pics replaced. Please observe our rules on photo posting.

i found the roland color library in corel draw, so i decided to print it out. i exported it the same way as always and it came out terrible. the colors have small dots through out it, its never a true solid color unless its 100% of that one color and 0% of the rest.

so i did more research, and i found versaworks has its own color library, so i was hoping i could print that and have solid nice colors to look at but i was wrong, it might even be worse! if the color is mixed just a little, it looks like "snow" on a old t.v. its just terrible. look at the pics, and yes it looks just like that! that is right from the versaworks color library.

I downloaded, installed and printed with the 3165gra profiles. set my vinyl length, not sure what else there is to change when i'm printing right from versaworks.

as of now all i use is gloss oracal 3165ra vinyl. should i try other profiles? generic 1 was worse.

i would love for this to be a simple answer but i think it won't. i'm dying to get this going and customers are bugging me to get there jobs done! any help would be appreciated!!

thanks

Matt

Offsite pics replaced. Please observe our rules on photo posting.

Attachments

Last edited by a moderator: