Cole Larson

ColeBL

This is probably going to make a lot of yall cringe!

But I am posting here in hopes to get some constructive criticism and learn more about the sign making ways. I am hobbyist woodworker and have acquired a new tool that has lead me down the path of making a sign for my wife's company to hang on the front of their building.

First off I am starting with cheap materials to cut down on cost as I struggle through some of the newbie mistakes. So I know the finished product will not be near as professional as most of the signs on here. But I am hoping it comes out well enough to simply work...

Finished sign will be 72"x41" and will hang 15ft off the ground on front of a metal building.

Materials and Tools (so far):

EPS Foam form Home Depot

Router Bit

Handheld CNC router

Sign Logo:

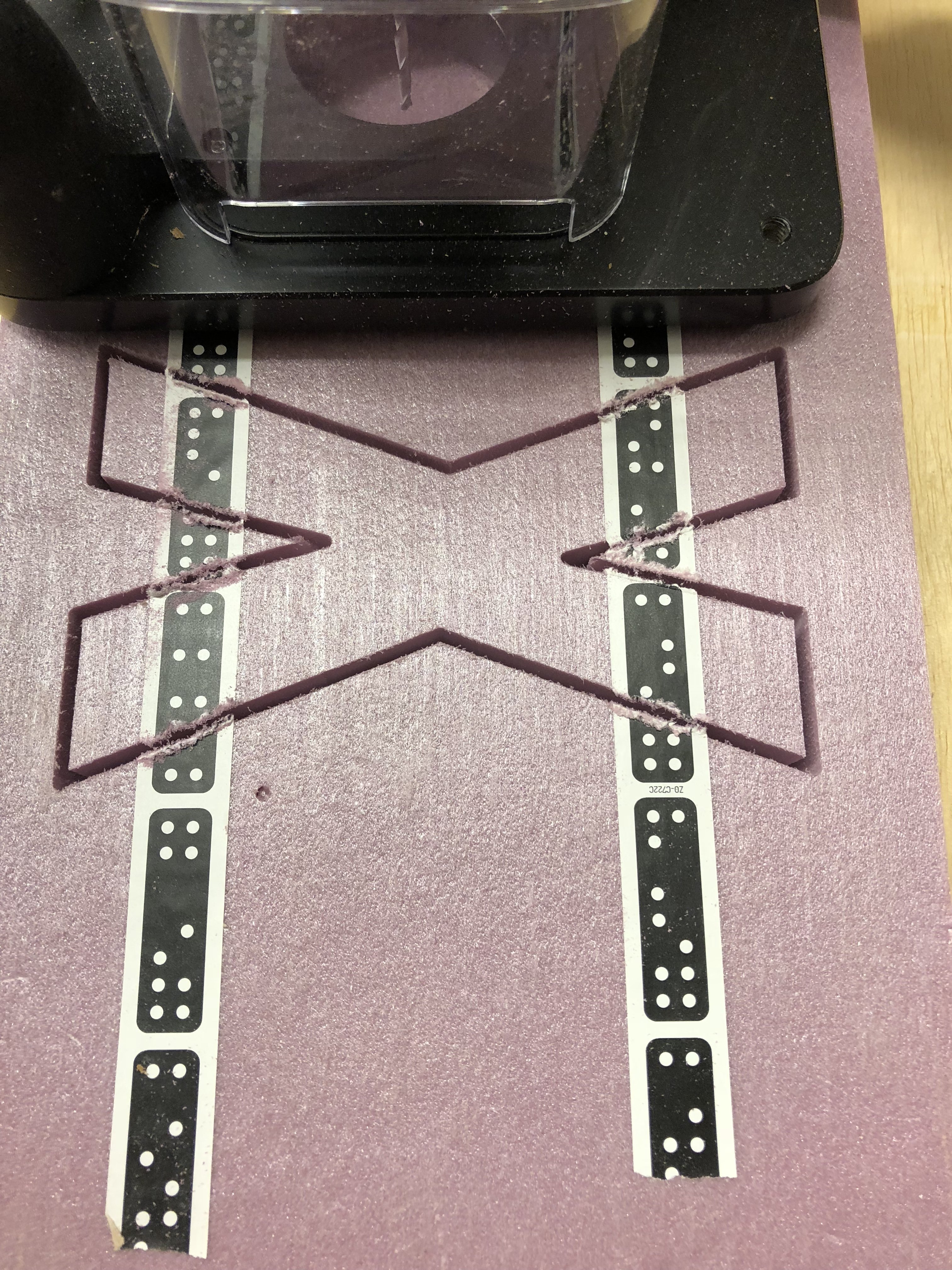

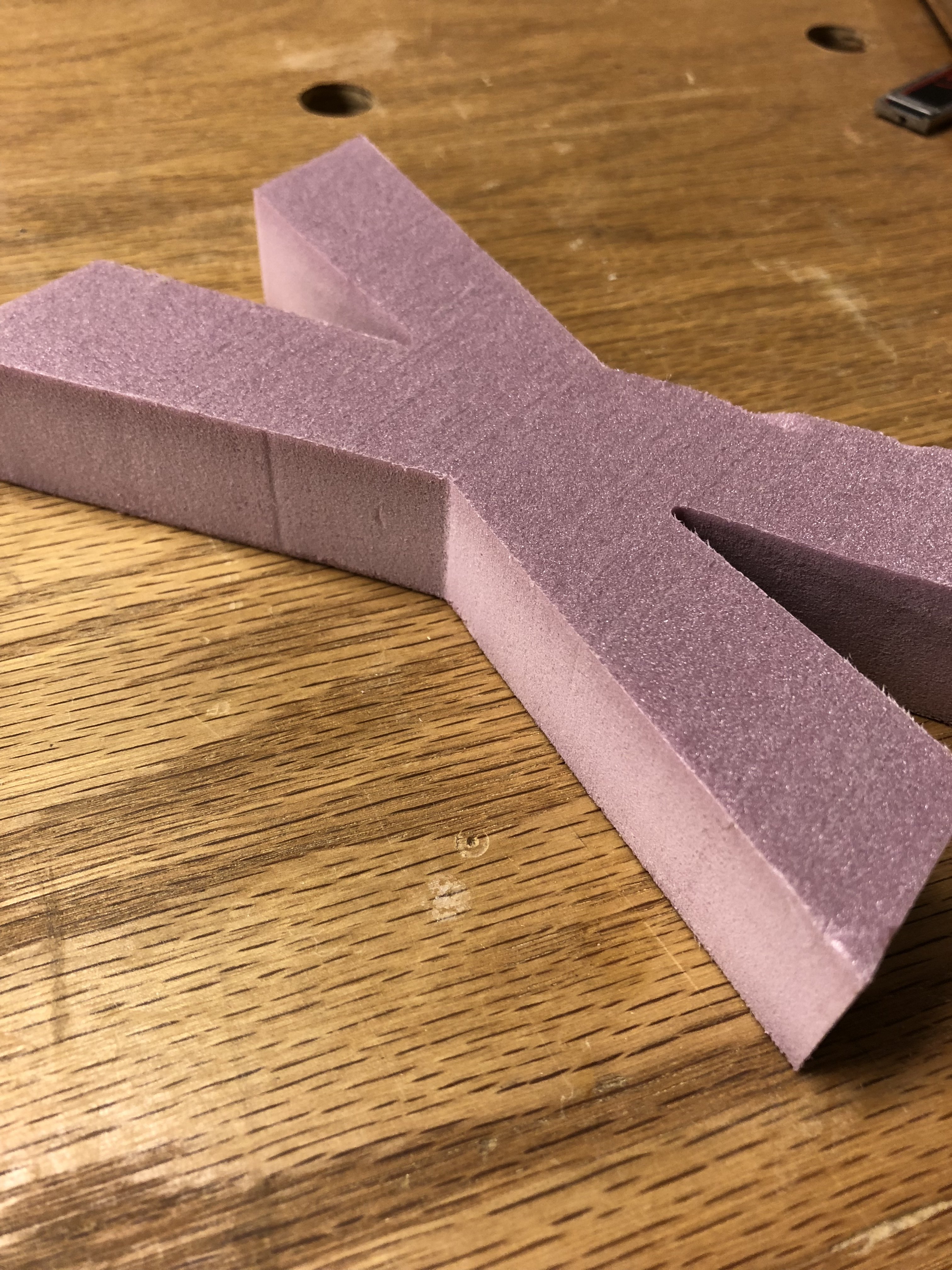

First Step: Test cuts and experimenting with glues

The foam cut well!

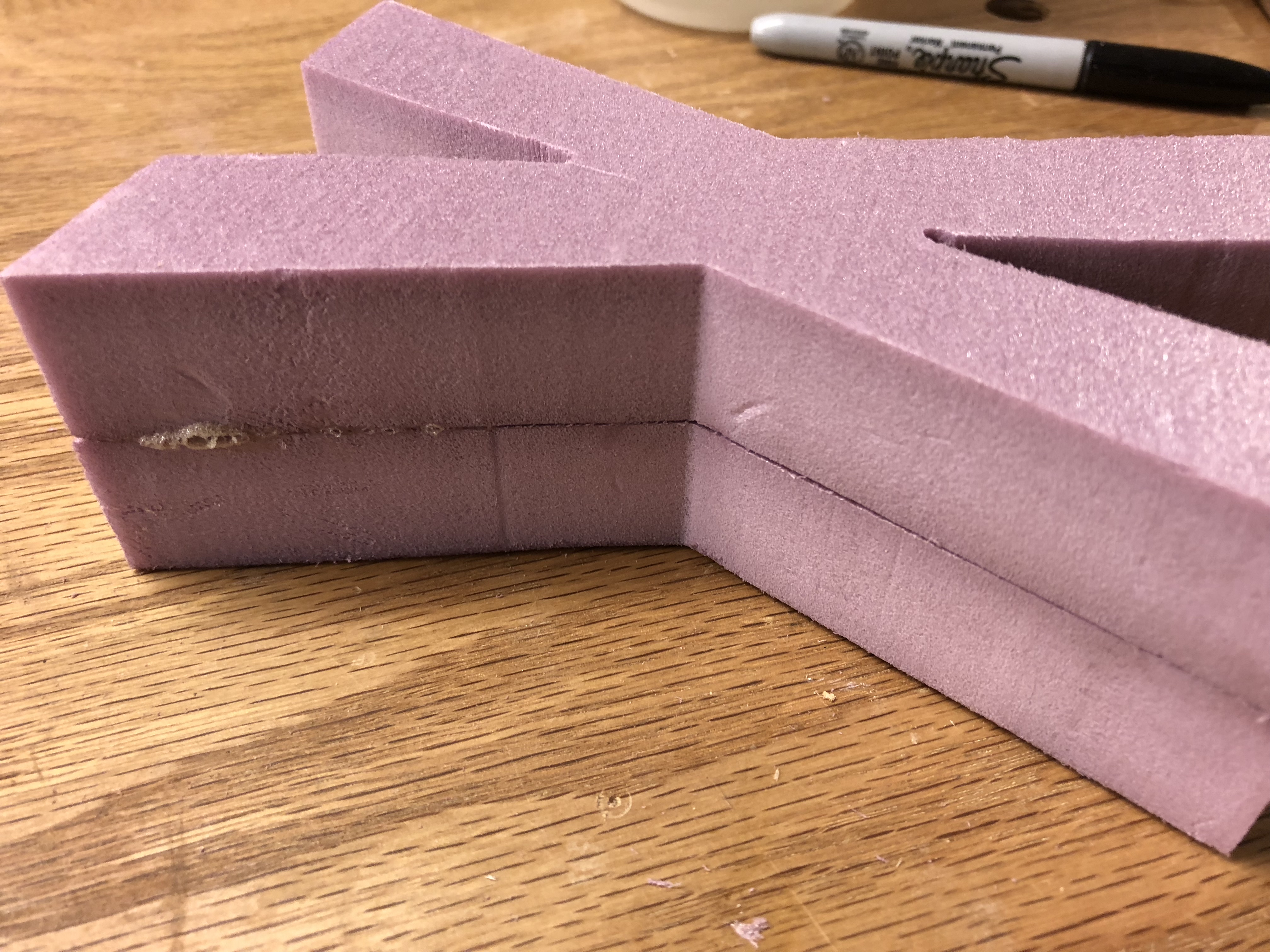

I have tested 3m Super 77 and Gorilla Glue. The Gorilla glue is the winner here. I can pull hard enough to separate two pieces with the 77. There is no way the one that was glued withe gorilla will come apart.

I just need to be careful on the amount of Gorilla I put down because I dont want all the foamy squeeze out.

But I am posting here in hopes to get some constructive criticism and learn more about the sign making ways. I am hobbyist woodworker and have acquired a new tool that has lead me down the path of making a sign for my wife's company to hang on the front of their building.

First off I am starting with cheap materials to cut down on cost as I struggle through some of the newbie mistakes. So I know the finished product will not be near as professional as most of the signs on here. But I am hoping it comes out well enough to simply work...

Finished sign will be 72"x41" and will hang 15ft off the ground on front of a metal building.

Materials and Tools (so far):

EPS Foam form Home Depot

Router Bit

Handheld CNC router

Sign Logo:

First Step: Test cuts and experimenting with glues

The foam cut well!

I have tested 3m Super 77 and Gorilla Glue. The Gorilla glue is the winner here. I can pull hard enough to separate two pieces with the 77. There is no way the one that was glued withe gorilla will come apart.

I just need to be careful on the amount of Gorilla I put down because I dont want all the foamy squeeze out.

Last edited: