filipa leite

New Member

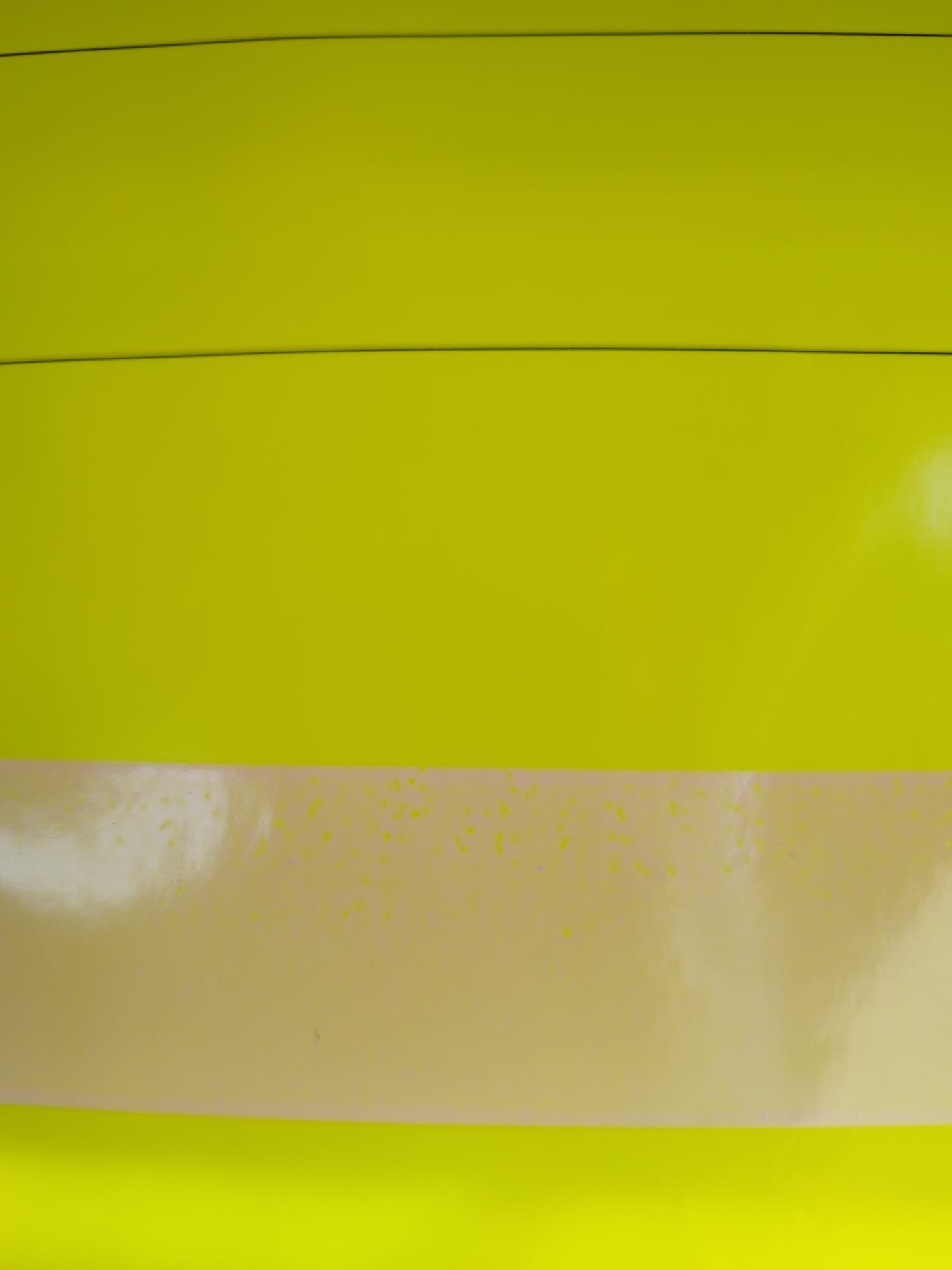

We make graphics kit for motorcycles etc. we have a roland truevis vg3 that prints white too but we are having problems printing on fluorescents The black comes out very well, the other colors don't, they don't stay even, has anyone had this problem and know how I can solve it??