heyskull

New Member

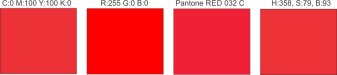

Of late I am seeing a lot of prints that look either fuzzy or with Reds than seem almost as if the ink is like when you get silicon issues when painting and it is sepearating.

Is their some sort of calibration and setup I can do as the test prints are perfect and the head has no lint?

Thanks

SC

Is their some sort of calibration and setup I can do as the test prints are perfect and the head has no lint?

Thanks

SC